Bobby: I tried wading back through your (and other's) posts but got lost. So, backing up, if it pops through the carb coming off idle to a slightly faster speed it is lean. Try turning your mixture screws in (one at a time) til it stumbles, then backing your mixture screws out 1/4 - 1/2 turn and see if that cures it - I would go as much as 1 to 1-1/2 turns if it needs it. I can't remember engine or carb size, but I've seen old Solex carbs that needed to go out 2-ish turns above stumble to run right. If that doesn't help, go up one size on your idle jets and start over with the mixture screws. Increase your jets, say, from 45 to 50 - BTW: a 45 idle jet, if that's what's in there now, sounds kinda small and may be the culprit).

Next step after that if, it doesn't improve, is to check the output of the accelerator pumps. On Dells, the pump adjustment is two-fold: Changing the accel. pump jets or adjusting the pump actuator lever. I assume Webers are the same. Adjust the pump actuator for more stroke/more fuel and see if that helps. If not, try going up 1-2 jet sizes for the accel. pumps

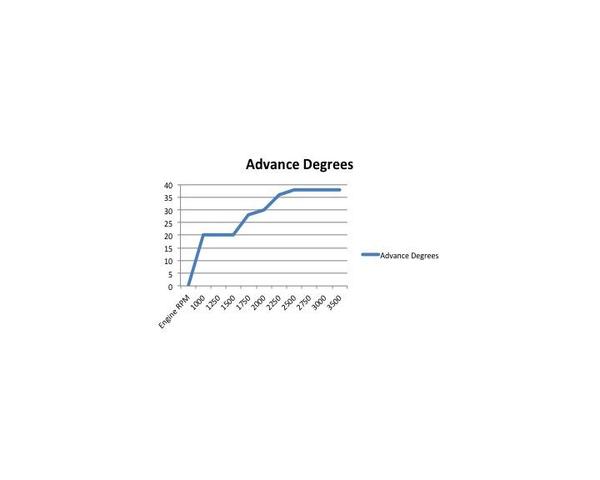

I do not set my Magnaspark advance at idle - with a centrifugal advance disti the idle setting is sort-of meaningless. Remember that centrifugal advance distributors were designed for commercial engines running at a single speed, usually 3000 rpm, all the time, like running a pump or generator. That's why most of them have a curve that looks like a step function. To set advance, I run the engine at 3,000 rpm and set the maximum advance to just below the detonation level for the gas I use, then back off 2-4 degrees if I'm planning a trip and don't know what gas I'll find. I went out and checked (just for the hell of it) and this is what I'm running:

Engine RPM Degrees Advance

1,000 20º

1,500 20º

1,750 28º

2,000 30º

2,250 36º

2,500 38º

3,000 and above 38º

Before everyone goes nuts about the bottom and top limits, it runs fine for me and my situation - Running on "89" Octane pump gas, it never knocks on hard pulls so I feel it is OK - if it knocked I could either run "high test" or simply run it back 2-4 degrees. PLUS I have never mechanically checked #1 top dead center with a probe through the plug hole to see if my degree wheel crankshaft pulley is even remotely accurate. The aftermarket ones are notorious for being weird. If it is off, God knows what I'm really running........ I suppose that I could keep advancing it til it does knock on acceleration and back off from there - THAT might prove interesting, too, as at least I'll find the knock limit for THIS engine with THIS degree wheel - other engine combos (compression ratio, cam, etc.) will probably be different.

BTW: IIRC, Tomlinson's book has a section on trouble-shooting different scenarios. Might be worth a look. He'll probably mention possible vacuum leaks, but if it idles smoothly without hunting (up and down rpms around a mean) then I wouldn't look for leaks.