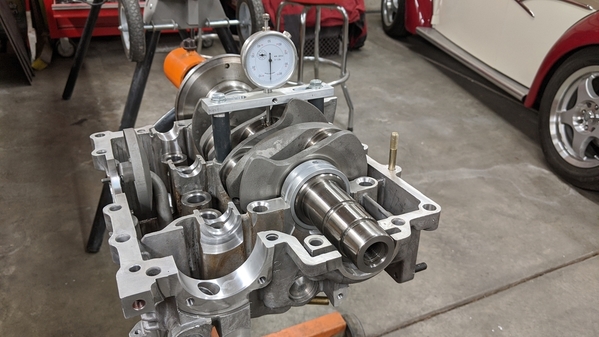

The engine is being built on a new mag case, fully shuffle-pinned, welded behind Number 3, and drilled for Hoover mods, with 911 piston squirters (to spray the underside of the pistons, for cooling) installed.The bottom end is a 4340 CroMoly crankshaft (84mm, Chevy journals, nitrided) and 5.4” forged H-beam rods with ARP2000 rod bolts. We’re using SilverLine steel-backed main bearings, double-thrust cam bearings, and Clevite rod bearings.

We’re using AA 92 mm thick-wall cylinders and forged slipper-skirt pistons with spiral-lock retainers. I’ve got a set of Deeves rings, with a Total-Seal second ring. I’m very much aiming for nice, round cylinders without blow-by no matter how hot it gets. We’re setting the deck at .040 and aiming for 9.9:1 compression.

I contacted EMPI, who had purchased Bug-Pack a few years ago, and found that they had one leftover dry-sump oil pump, which I snapped up. This was like finding a diamond in a pile of coal, only less likely. The pump has plenty of volume to feed the squirters, etc. I was super jacked up about finding this, as it means I can leave the 2276 alone.

The valve-train is where I’m getting carried away. I’m using the CB 2292 cam, clearanced for stroke, and CB 28 mm ultra-light lifters with the Hoover mods. The heads are CB Panchitos… with a twist. I got new stainless 3-groove valves, and a set of Dan Ruddock’s “Beehives Done Right” valve-springs/retainers. The beehives are a single spring with lower seat and nose pressures, which can still control the valves at over 7000 RPM. As a result of the lower spring pressure, I’m running HD aluminum push-rods and will be able to get by with a stock (helical cut) cam gear, machined to be adjustable. The valve-train should be quiet, light, and (most importantly) produce less heat than a more traditional dual-spring hi-performance setup. I’m also going to run early MK1 Rabbit valve-seals in the heads. I sourced a set of PTFE seals that should hold up to the heat. Not many people do this, but I’m hoping it’ll be worth it to keep oil out of the combustion chambers.

The entire thing will be blueprinted down to the gnat’s eyelash. This is where a machinist can do his OCD thing when an assembler (like me) would pretty much just bolt things together, and why I decided to have VintageVolks do the entire longblock. I’m getting updates as we go on every measurement, and how it relates to everything else. The spread-sheet is very, very detailed, and building this engine will take probably 8 weeks total.