It's time for installment 2 in the "step towards (relative) sanity "series, whereupon our protagonist attempts to restrain Mr. Hyde and allow Dr. Jeckyll full control of his car.

I believe that when we left off (pre-COVID), we were merrily prepping the bottom end. It's a long/boring story, but there was a problem that involved QC with the new case-- a problem which involved the cam bore being offset, etc. The case would be fine for a less involved project, but we all decided that for something with as many "extras", we'd be best off to start over. One step forward, two steps back. The good news is I didn't supply the case, so it's not my responsibility. The bad news is mid-lockdown, it's hard to know when a new case will arrive at the machinist's.

VintageVolks has been fantastic throughout this process-- really, really stand-up guys.

So, attention was turned to the heads.

As discussed, I'll be using the new Panchitos. Normal people just order the heads they want, and bolt them on. Normal people are happy. Normal people don't try to make very nearly perfect things more perfecter. The problem with the protagonist of this ongoing saga is that he has a hard time being "normal", even when normal has been demonstrably better.

My Panchitos were ordered "built" like most people would-- valves, guides, seats, dual valve-springs, and cromoly retainers installed. CB sells them bare for idiots who think they can do better, but I had resolved to be good and try to blend in. I got my heads, and they were beautiful. And alas, I yam what I yam.

Typical "H/D" single valve-springs lose control of the valves with pretty mild cam profiles at pretty low RPM. I have been looking at bee-hive valve springs for a couple of years. Beehives are single springs wound differently than standard, which allow more aggressive cam profiles and higher RPM without setting up a harmonic that causes the spring to lose control of the valve-train. They've been used in the V8 world for years, but have not been used in ACVWs because of what is commonly available. There's a guy named Dan Ruddock who's come up with a pretty interesting way to use them in ACVWs. Dan makes a couple of different sets for different applications and calls them "Beehives Done Right". The idea behind beehives is the promise of being able to accurately control smaller valves (like the Panchitos) up to 7000 RPM with very low spring pressures. This is important for a couple of reasons:

High spring pressures create a lot of heat and a lot of wear. Everybody is (rightly) worried about the cam lobe/lifter interface-- this is the primary reason car-guys get all bent out of shape about the zinc and phosphorous content of motor oil. ZDDP in oil is "sacrificial", and is meant to provide a shield between the cam lobe and lifter face in an extremely high shear wear situation. Everything becomes critical with super high valve-spring pressures, and the cam lobes and lifter faces live an exceedingly hard life.

High spring-pressure require very robust components-- straight-cut cam gears, very strong pushrods, and rocker-arm assemblies that look like they are built to hold up a bridge. Big components are heavier, and heavier components require more spring to control. It's a viscous cycle that gets some guys running K800 springs on the street.

... but for me, probably the main consideration is that the friction created by the springs jamming the lifters into the cam creates a huge amount of heat-- heat that goes straight into the oil. Heat that is hard to get rid of. Heat that kills engines.

Unsurprisingly, I decided I had to have them. As I said, my Panchitos arrived ready to go with sensible (not obnoxiously heavy) dual valve springs, valves, guides, and seats. The "Beehives Done Right" kit requires valves ground for "normal" triple groove keepers. CB's heads come with single-groove valves and keepers-- so getting to the beehives would mean removing and setting aside not only the valve-springs and retainers, but the valves themselves. Undeterred, I sourced and ordered 8 new valves and the appropriate kit from Dan Ruddock.

In addition, I decided I wanted to be in the .001% of the ACVW guys out there who run valve-stem seals. The 4 people in America (Bob Hoover among them) who believe this to be worthwhile run early Rabbit valve-seals (P/N: 026 109 675), because they will fit VW valves and the normally used guides (if they are turned down), and the OD is small enough to clear a compressed VW dual valve-spring. Fortunately for me, my machinist is one of the guys who believes in this modification. I found a guy on TheSamba who had a set of TPFE Rabbit valve-seals, which I picked up. TPFE has a very high heat tolerance, as compared to Viton.

Unfortunately, once the valve-springs were removed, this is how much guide was sticking out of the spring boss:

As you can see, there's not enough meat to attach a seal to the guide. This left us three options: 1) cut down the boss to expose more guide, 2) just ditch the valve-seal idea, and steer this ship towards more conventional horizons, or 3)

So, what we have accomplished is to successfully take a set of fully built and perfectly good heads and proceed to:

- Remove and set aside the valve-springs and retainers

- Remove and set aside the valves and keepers

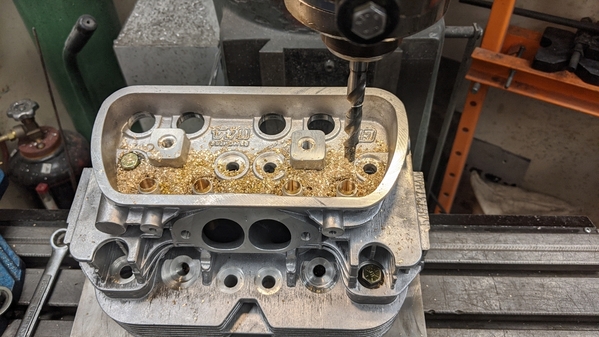

- Drill out the installed valve-guides

It's a good thing I've still got the seats. I wouldn't want to have purchased complete head for nothing... ![]()

It seems to be raining. I'm happy.

More details soon.