Getting back to the engine (and the madness)...

As I said in the opening monologue, I’m using Panchitos with Dan Ruddock’s beehive spring kit. The plan was to use a CB2292 and 1.4 rocker arms, as this is the combination that got 180 hp for Anand’s 2332 (Pat was recommending the 2292 with 1.25 rockers). Everybody always says, “the power is in the heads”, but the truth is that the heads and the cam are a married couple-- one is only made complete with the other. Cam selection is very, very important.

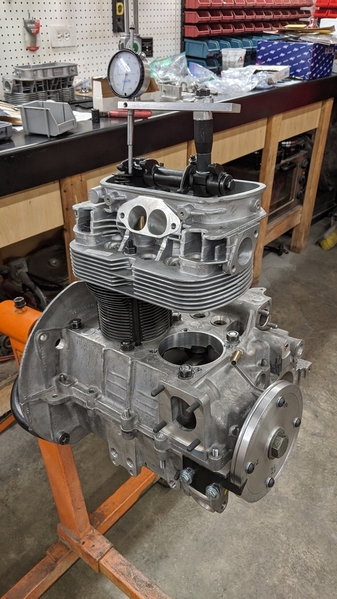

The Dan Ruddock beehive springs will allow .550” of lift before coil bind with a “standard” installation (1.7” installed spring height), and a standard installation has the right seat and nose pressure (the amount of force exerted on the valve-train when fully closed and fully open). The idea is to run lower spring pressures, while still controlling the valves-- so that there is less friction at the cam/lifter junction, and less wear and tear on everything else in the valvetrain. I’m using CB’s lightweight lifters, aircooled.net’s heavy-duty pushrods, and modified stock helical cut cam gears (which require a low spring pressure).

The CB 2292 has .378” of lift at the cam. Doing the math (and CB has the math, right on their specs for the cam), using 1.4 rockers works out to .529” of lift at the valve, which is well within the range of the beehives. I put all this stuff together having done all the calculations, and sent it out to Jason. I was a genius!

… except when Jason mocked up the valvetrain, we came up with .557” of lift at the valve-- too much lift for the beehives. Huh?

Well, it turns out that all of the economical “1.4” rocker arms actually measure out to 1.45:1 or greater. Mine figured out to north of 1.47:1. Pauter (of course) makes a true 1.4:1 rocker arm assembly, but they cost $650, and are good to about 10,000 RPM, which seems like a bit of overkill for an engine that won’t see over 7000 RPM.

Panchitos are done flowing at about .500” of valve lift. They only flow 4 cfm more at .600” than they do at .500”, so there isn’t much point in lifting past .500” anyhow. The thing is: if I lift to .530” or so, the valve actually spends quite a bit more time above .500” (where it flows the best) as the valve opens and closes. In my mind, I really wanted as much “dwell” as I could get at around .500” of valve-lift.

Cams are super cool. When we look at the specs, all we can see is the total lif and the total duration. We can’t see the shape of the lobe. Some cams lft really fast and have a very long dwell at maximum lift (which makes more power), but these cams are noisy and super-hard on the valvetrain. Other cams lobes look like a splitting wedge-- very pointy, with slower ramps, but way less time at maximum lift. The result is that cams with nearly identical specs can be different enough for one to be preferred over the other. The 2292 is very like an Engle FK10, which is very similar to a Web 86c.

It’d be neat if you could use whatever cam you wanted with whatever lifters you wanted, but the metals often don’t play well together. CBs lifters are super-lightweight, which is the theme of this entire endeavor, so using a cam ground on an EP-12 blanks (like CBs are) was kind’ve baked in the cake.

So I was stuck. But, I had an ace up my sleeve! In anticipation of needing them someday, a while back I had bought the last set of CB’s “1.3” rocker arms I could find (they are a discontinued item). If the “1.4” rockers measured 1.47:1, I hoped that the “1.3” rockers would measure 1.35 or so. I wanted at least .500” of valve lift. I sent them out to Jason.

He put them in and measured them up. We had .489” of lift, which is about 1.29: 1 . I should have been happy. I wasn’t. I really wanted the valves to lift where they would have with true 1.4:1 rocker arms. I really didn’t want to buy Pauters.

I put the query out on TheSamba, fully expecting a bunch of unhelpful and non-related responses. Instead, I got a lot of good information. and found that “1.25” rockers often lift up to nearly 1.4:1. I briefly considered this option, but decided I really didn’t want to end up with 4 sets of rocker arms and none I could use. I also got a response from Dan Ruddock.

Dan knew this was a problem with his springs, and he had a solution. He’d contacted Web Cam, and had found a grind (the 252), which was not in the catalog. This cam has .366” of lift at the cam, and 260° duration (at .050”). He had the cam customized with more duration-- either at 266° or 272° with the same lift, and had it ground on an EP-12 blank (because he knows those lifters are the bomb). The CB 2292 cam has 270°, which is really aggressive. The Web cam has nice easy ramps, and a “snub nose” for a lot of dwell at full lift. A bit less aggressive, with easy ramps and a lot of dwell-- it sounded really, really good.

The valve lift figures out to .538” with the “1.4” rockers (that measure 1.47:1), which keeps me well under .550”. Web cams are legendary for making power, and being easy on the valve-train. I chose the 266° duration cam. I didn’t want to deviate from the recipe, but I ordered the cam and it’s at Jason’s shop.

When one colors outside the lines, it gets weird pretty quickly. Stay tuned for the next exciting episode of "Stan's Lawn Mower Engine".

This is a step towards sanity, remember?