For those that have never looked at the cooling fan closely and don't know why it would come apart- the first pic is of a stock type 1 fan. You can see the ends of the blades have little tabs that are bent over but not welded- that physical contact is all that's holding the assembly together. Before you start thinking "kind of shaky", remember that stock fans never come apart in stock engines. As you increase the rpm's the stress factor either doubles or quadruples (I can't remember which) so you can see how spinning it faster would do it in. The design, although perfectly adequate for a stock engine (maximum rpm 4500) just doesn't hold together at 6 and 7,000 (and apparently even 5600) rpm's. Also remember that with stock pulleys the fan is spinning at 1.8 or 2 times faster than the engine- at the redline of a modified engine that's pretty fast! Note that the center is worn- probably not torqued to spec?

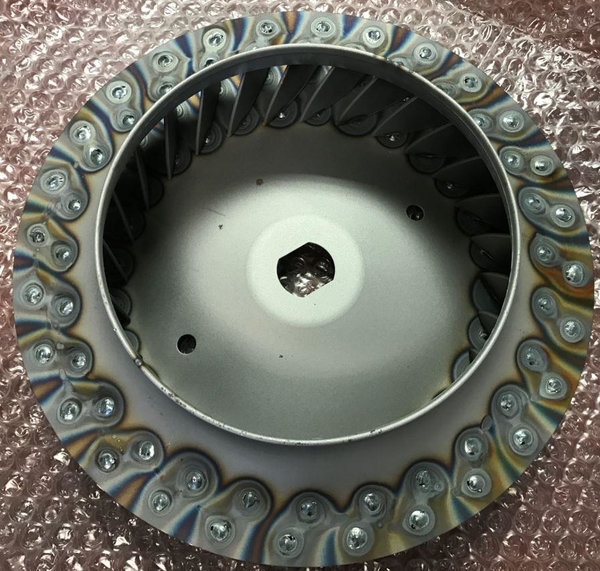

This is a tig welded fan- if not already, it will need to be balanced because of the added material. It will not come apart. It's also brand new- no rust and the center is in pristine condition.

I think I mentioned it in a post above- I've heard of the tabs being tig'd without using any filler rod (just melting the tabs to the outer shell) so there's no weight increase (I do like that!![]() ) and more importantly, the balance shouldn't change.

) and more importantly, the balance shouldn't change.