To be honest, I don’t really like the dipstick. It’s chrome and smooth, so you can’t tell where the oil mark is, unless your oil is old and dirty. It doesn’t seal against the top of the dipstick tube well, so there’s a potential leak point. And having wires attached to the top of the dipstick makes it a right pain to pull it out, wipe it clean with some tissue, reinsert, then pull out to check the oil level. But until I get under the Porsche-style fan housing I can’t see where else I can put an oil temp sensor that is in a good position. Now I’ve written that, I think I’ll do a search tomorrow morning on here to see where y’all have your oil temp sensor on a full flow system.

Goodnight all

This is exactly the kind of thing that happens.

@Martin's Eleven (UK) posted:Well, the dash lights problem turned out to simply be an old dodgy light switch, so I cleaned up the contacts using contact cleaner and compressed air, and that was that. Sorted.

As for the oil temp gauge reading maximum as soon as I turned on the ignition.. Well, this is embarrassing, but the car has a dipstick temp sensor, and I’d obviously disconnected and reconnected the feed and earth the wrong way round on the dipstick! Problem solved. :-)

Don't feel bad. Two winters ago, I made a big project of replacing my cooling system with a new Thing shroud and OEM thermostat flappers, etc. I got the final parts I needed on Tuesday afternoon and set about installing them.

About 5 o'clock on Friday, I finished the last details and tried to fire it up. Only to realize I'd hooked my distributor wires backwards and burned up my point and condenser. Right after all the shops had closed for the weekend.

To add insult to injury, my coil measured fine with my Harbor Freight digital multimeter and I chased a partial throttle misfire for a month, thinking it was an issue with my carbs. Once I pulled out my antique Simpson 260 analog multimeter, I realized my coil was hopelessly NFG as well. A new black coil from FAST and a yellow Bosch sticker from eBay and it ran better than ever.

And it hasn't run hot since!

Wasn't it Stan that said, "90% of carb problems are electrical?"

Something like that. You can't beat a 40-year-old Simpson. They sell for low bucks but are reliable as heck. That's my go-to even before a Fluke digital multimeter.

I just recently bought a BitScope BS05 USB Oscilloscope to watch the waveform on a pulse generator that will soon be controlling my gas heater. For about $50 bucks I got a full blown logic analyzer the likes of which cost us $150,000 when we needed them back in the very early 1980's. I am blown away at how the costs of computer related stuff has come down in the past 40 years - Especially in the last ten years.

@Gordon Nichols posted:Something like that. You can't beat a 40-year-old Simpson. They sell for low bucks but are reliable as heck. That's my go-to even before a Fluke digital multimeter.

Heh, heh, heh, I got mine for free.

Long story short, I was perusing a state surplus warehouse when I found a PALLET of NIB 260's. Talked my supervisor into buying 3 for each of our venues and "Hey, as long as we're buying 3, my birthday is next week."

My fluke, otoh, which I did pay for, is now world's most expensive continuity tester after I dropped it from about 2' high.

Simpson made all the old K-S meters for telco use. I might have one, but I can't remember.....they don't use them any more. Now they use a meter called a Sidekick. I never had one, did all my troubleshooting with the trusty old Simpson. Dead reliable, like a hammer, always works.

Yup. Looks just like mine. Give 'em a blast every 5 - 8 years and they keep on working.

Contact cleaner is good stuff.

@DannyP posted:Contact cleaner is good stuff.

30 or so years ago I found out about Caig ProGold.

I started using it on auto/moto connections soon after. Every time I make/break a connection, I give it a dose. It's a cleaner/deoxidizer plus a protectant. It's expensive but it's worth it's weight in gold. Hence the name.![]()

A little goes a long way. I still have about 1/4 left of the can (like above) I bought in the 90's, but TBH, the best formats for automotive use are the pin oiler and this little "trial size" kit you can buy on Amazon. (The kit comes with fader lube, which is useless for garage work, but it's got enough of the cleaner and cleaner preservative to make it worth it.)

Attachments

Oh dear, I spoke too soon.. All I seem to have done is push the problem down the road. So, having supposedly fixed the lights, I take the car out for a final 'test drive' this afternoon before I have surgery on my wrist on Monday - which will mean no driving for a month or two. Over the top of the deafening exhaust, I heard a solenoid clicking like crazy. I pull up behind another car at a T junction and see my headlights are flickering on and off and then end up staying on full beam.

So I recheck the light switch - even when it's switched off the headlights are on. I head under the bonnet and eventually the only thing that works is to pull the blue lead off the relay which I'm guessing is the main/dip relay, and the headlights go out.

I guess I'm being paranoid after reading about fires being the major risk factor with fibreglass cars.. But better safe than sorry I say!

So it's back to the drawing board on the electrics - I've downloaded the wiring diagrams from the library here and I'll work through that this weekend. To be fair to Chesil (as was), the state of support for kit builders was pretty poor 20 years back. It was very much a 'working it out for yourself is part of the fun'. Like pretty much anything back then - there just wasn't the focus on customer service like there is these days.

Talking of fire risk, remember the exhaust/bodywork interaction pics I posted at the top of this thread? Well, I did what I could in terms of strapping some heat shield fabric between the exhaust and the body, but it's not enough - the heat shield works best for radiant heat, but this gap is so tight, it's conductive heat. So I pulled out my IR temp gun when the engine was up to temp (after 10 minutes reasonable motoring), and opened up the engine bay to see a wisp of smoke coming from the slightly oily heat shield. As you can see the heat shield (from the engine bay) was 278°C - that's 532°F in old money..

So you can see why I'm paranoid at the moment. Time to put the car away until my wrist is recovered, and in the meantime I need to find a local specialist exhaust fabrication company that can cut a small wedge out of the exhaust , reweld it and steer it away from the body. (and at the same time swap that muffler and trumpet end pipe for something quieter). And perhaps get it ceramic coated for further temperature reduction?

But I'm still loving it! :-)

Attachments

And to prove it, I took a couple of quick pics to show the new attitude of the car (lower front, slightly raised back) after I adjusted it earlier this week.

Scrumptious!

I've got this madness good and proper!

Attachments

Really nice looking congrats.

It looks like the more serious problem now is getting the exhaust away from things that might catch fire.

Once that is done (and your wrist is healed) there's some diagnosing to be done about the electrics.

My first question would be, do your headlights have a 'flash-to-pass' feature? In other words, when your headlights are OFF, is there a spring-loaded button you can activate to momentarily flash the headlights? Sometimes this is incorporated in the turn-signal stalk (push the button or pull the lever and the lights flash).

(This is usually the same button you use to switch between high and low beams when the headlights are ON.)

Not all VW's (and not all replicas) had that feature, but if you do, that would help in diagnosing why your lights are on even when the headlight switch is off.

The rest of the explanation is a little long-winded and not worth going into if you're not wired for 'flash-to-pass'.

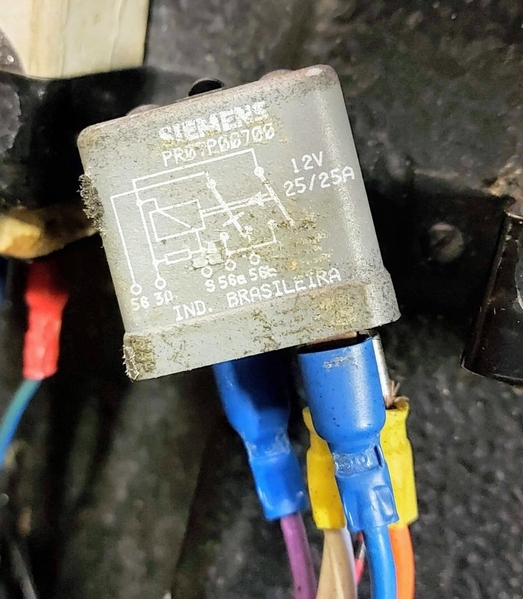

(Looking at the wiring diagram on the relay in your photo, I think you do have 'flash-to-pass' even if you may not have discovered it yet.)

Good afternoon (UK) and morning (USA) all. Hope you're enjoying your weekend.

@Sacto Mitch - many thanks for your help. It does indeed look like I have a 'flash to pass' feature. The original Beetle was a late 1970 and has the main/dip and flash function on the indicator stalk. The Chesil build manual has limited electrical info, but it does list all the relays, of which there's this:

Which explains why pulling the purple lead shut off the headlights even when the ignition was off. I guess I need to check another relay in case it's that (the existing one does look very old) and also the switch unit on the steering column in case that's shorted or similar.

How do Chesil wire colours compare to existing VW colours? They're not colours I remember, although to be fair the last time I worked on a Beetle was 1990..

The Chesil manual states:

- All black wires are earth

- All light green wires are fused and go via ignition switch

- All purple wires are fused but not switched via ignition

So that would explain the purple being a permanently live feed to the flasher relay.

As you say, the exhaust is the more serious problem to solve, but that can be put on the back burner (narrowly avoiding the pun) for a while whilst I can't drive. I'll do some research locally for a decent exhaust fabricator. An initial online search seems to result in finding websites for 'Performance exhaust services' that define performance as 'loud and deep' (as the actress said to the Bishop). I need to find someone who listens to what the customer wants.

Attachments

A quick update. My wrist still being in plaster (ligament surgery) means I'm having to bide my time on any kind of spannering. However, I thought I'd have a go at aligning my gear shift because it was very tricky to get into first and going from first to second would sometimes graunch the reverse gear - yikes..

So, thanks to this site and YouTube (as well as my secondhand Bentley manual from Ebay), I thought I'd check the play in the connections before trying to adjust the gear lever mount. After all, everything else I've looked at on this car is either worn or needs adjusting, so I might as well do it right and future proof everything.

The gear shift guide bush looks and feels tight - no play between shaft and bush.

The gear shift coupling, however, is a different matter. About 2mm fore/aft slack in the bush, and a small amount of rotational play too. So I need to replace this.

Question, which coupling option do I buy - urethane or stock rubber? I normally err towards stock/OEM rubber rather than urethane for most parts (eg steering rag), but perhaps this is one part that benefits from urethane? Answers on a postcard, please. Thanks :-)

Also, I noticed the steering rag really does earn its place in the car, given the difference in angle between the shaft coming out of the steering box and the steering column - it's around 5 degrees.

You can see the amount of flex the coupler has to cope with. I think this is mainly due to my car being right hand drive and the steering box has the shaft on the left hand side as you look towards the front of the car, so there's extra displacement to cope with compared to LHD cars?

The whole arrangement means the steering wheel is definitely skewed compared to the dash:

Looks like this is a case of "They all do that, Sir" - unless I convert the steering to utilise universal joints..

Attachments

@Martin's Eleven (UK) - While I am not knowledgable enough to respond to your questions, your picture did bring something up worth noting. I see your car has a crush coupler on the steering shaft. At our recent tour of the Smoky Mountains (Tour de Smo') one of our group had a catastrophic failure of his coupler. Luckily it was at the last turn to put his car in a parking place at the hotel after a day long, very vigorous run on twisty roads. Given his obvious good fortune we encouraged him to go out and buy some lottery tickets.

I encourage you to go to the "2020 Tour de Smo' - after all" thread in the "Events" forum and see the video. The general consensus is the those couplers, after many years of use, are probably all fatigued and likely to fail, and therefore should be removed/replaced.

Good luck with your project and I hope your wounded wing heals quickly.

Hi @Lane Anderson thanks for your kind wishes for my recovery - the cast comes off next week and then it's a lot of physio.

And yes, I'd got the message on the crush coupler (see halfway up this thread) and that is on the 'to do' list once I get a few more things in order. The list is so long that I've got a full blown Trello board up and running with separate columns for each major area.

Some are relatively easy, some are more complex and need professional help, and this is one of latter (I can't weld). So these will need doing in a kind of waterfall project plan - you can tell from this that I'm a techie geek..