Late last season I noticed a chirping sound from the engine when very warmed up in hot outside temps. I thought it might be the alt belt and changed it out late last year in prep for this new season.

Recently on vacation in Florida it got a full test. Again, in hot ambient weather and with the engine well warmed up the chirp sound came to life and even a bit louder than I remembered from late last year. I tried the old belt dressing treatment and it did no good.

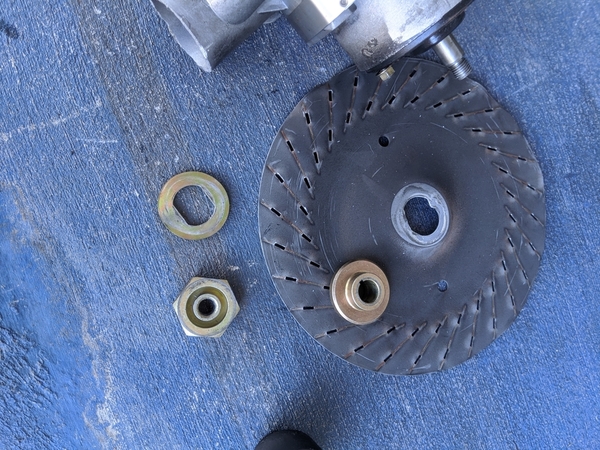

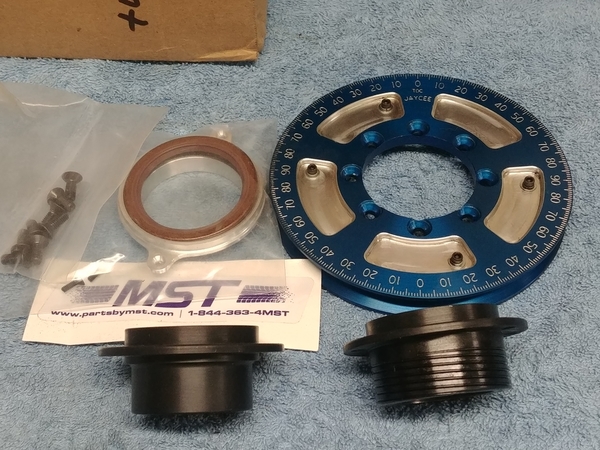

I can't seem to find a good alternator to cooling fan drawing online so my question is please, does anyone had an idea what may be chirping? My thoughts are to remove the fan belt and spin the alt by hand and hope to detect a bad bearing in the alt. Is there another bearing at the back of the alt by the fan housing that may also fail and cause the noise ? Ideas ? Thanks.