I told my wife that after we are both retired I want to look for a four car garage with a small house attached to it. As of now I have a two car garage with a large house on a large lot that I can't put a big shop on.

I had this opportunity, and blew it.

In 2006, I build a giant house in a 1-street subdivision about a mile east of town. In 2009, I built a 1500 sq ft barn with a heated floor and a 14' x 18' overheard door behind the house. My kids got married and moved out within a year or two of building it, so my wife and I were rattling around in a 7 BR, 4-1/2 bath house. We housed everybody and their uncle (3 different displaced families for 6+ months, students from church for entire school years, etc.), but Jeanie always felt weird living in the "big house". I did not. I always patronizingly told her if somebody pulled in my drive and made me an offer, I'd sell it.

In 2015, a friend did just that-- drove in the drive and made me a decent offer. It's a long, strange story, but the bottom line was that I sold with no plan where I wanted to go. Lots of cash in hand, free as a bird.

Anyhow, my dream idea was to build a carriage house-- 4 car garage downstairs, loft above. It would have been no problem in unincorporated Tazewell County, but Jeanie wanted to live in civilization, and we'd done it my way for 30-ish years, so... we built where she wanted to live (in town, in an older neighborhood).

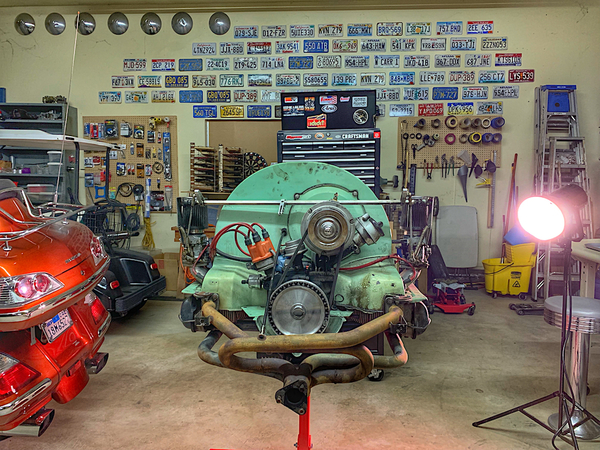

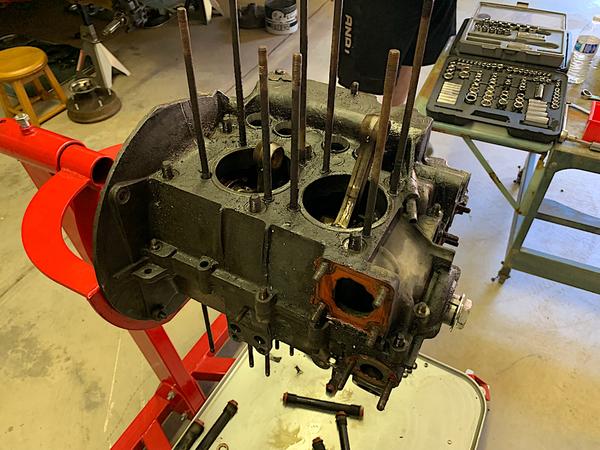

The thing is: most municipalities lack imagination and frown on unconventional ideas. If I'd have known then what I know now, I might've pushed harder, but what I ended up building was not at all what I had in mind. I'll post pictures of the shop when I finally get it finished, but suffice it to say, I'm squeezing 10 lbs in a 5 lb sack. Many, many hoops were jumped though for a shop space that is very, very nice, but quite a bit smaller than what I moved out of. Jeanie's got her dedicated parking, free of metal shavings. I've got a shop that has a 2-post lift, and will hold 3 vehicles in a pinch. Space is tight enough that I hung a 2-stage, 80 gal Quincy compressor from the 12' 8" ceiling above the blast cabinet. You've not yet begun to spend money until you start doing crap like that. The cost per square foot was staggering.

The guy that bought my place is in high cotton, however. He put two 2-post lifts out in the barn, and uses the 3-stall garage on the house as a garage (where's the fun in that?), and is happily frolicking around in a house with 2x the floor space as what I built for similar money.

I've done it both ways now and my observation is this: fitting a working shop on a smaller footprint is exponentially more difficult than just having a nice (normal) garage attached to the house, and a big, beautiful, dedicated out-building as a shop. Squeezing stuff in a small space is expensive and super time-consuming. Good luck with the zoning for more.

There's a reason Americans like big stuff. Turns out, it's just easier and better.