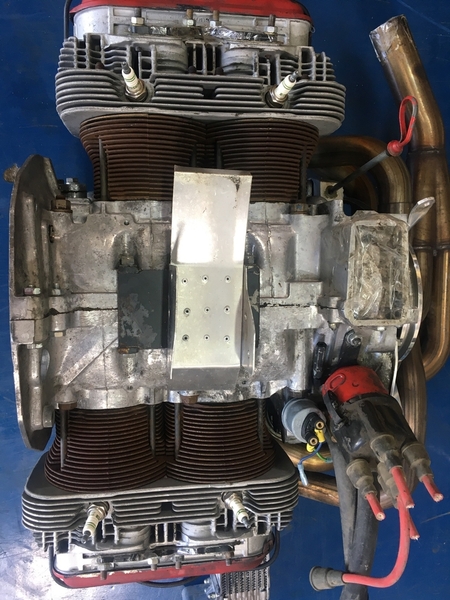

It would make sense that the exhaust valves in a RAT Type 4 would be 36 mm (and not 38 mm) if the intakes were 42 mm.

A while back, a really smart guy over on TheSamba (Glen Urban, or "Modok") posted a "golden rule" of engine design regarding I/E (intake/exhaust) ratio.

.86 is kind've the magic number for things to play nicely together. There are deviations, of course, meant to accomplish one thing or another. I'm not sure if these rules apply to all engines in general, or to pushrod air-cooled engines in particular, but I'm assuming that ideal always falls within a mathematical range.

Anyhow... as per Glen, the ideal exhaust valve is 86% of the intake valve size. The exhaust port is 86% of the exhaust valve size. The exhaust port ID would be 86% of exhaust header tube ID. On the intake side, the ideal intake port size is 86% of the intake valve size, and the ideal venturi size in the carburetor would be 86% of the carburetor bore, with runners that are 86% of the intake riser/carb bore.

When you apply the math to formulas that are known to work well, they pencil out almost every time.

In this scenario, a head with a 42 mm intake valve would ideally have a 36 mm exhaust valve. The exhaust port cross-section would be about 31 mm, and the header ID would be the same size as the valve (36 mm, which is incidentally about the I/D of 1-5/8" 16 ga. exhaust pipe).

The intake port would be .86 of 42 mm (36.12 mm), and the venturi in the carb would match this dimension (or exactly the standard size of a stock vent in a 44 IDF).

Stuff like this fascinates me. The further down the wormhole one dives, the more it becomes clear that we live in an orderly universe with general rules that just work (see @Sacto Mitch's explanation as to why a V12 sounds so good).

To my way of looking it, God (rather than the devil) is in the details.