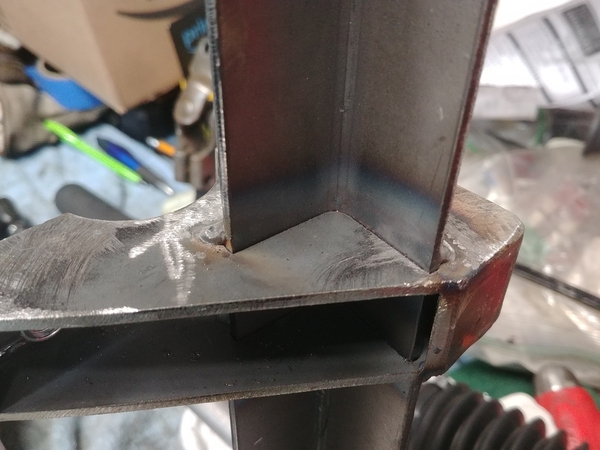

Here are the parts as I received them, but after cleaning all the packing tape adhesive and mill-scale:

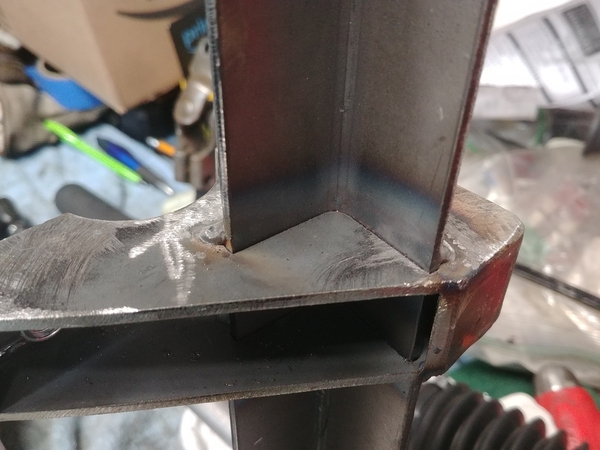

These welds penetrated well, you can see the bluing. Parts are all laser or water jet cut and fit well:

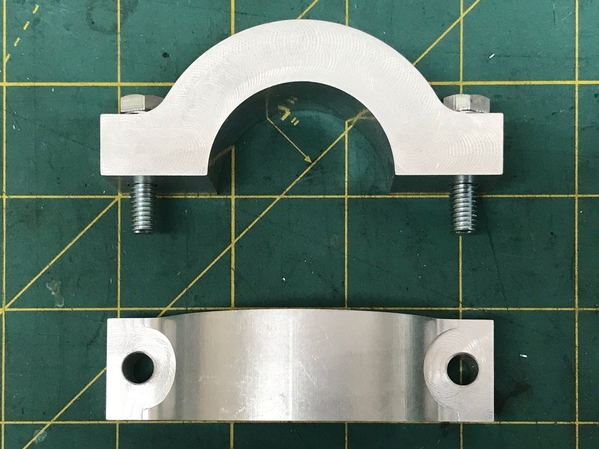

I was able to get the paint sprayed on today. Tierod bracket is machined from one billet 50mm piece. I like the use of the nutserts on the rack bracket. Rack bracket and tierod bracket:

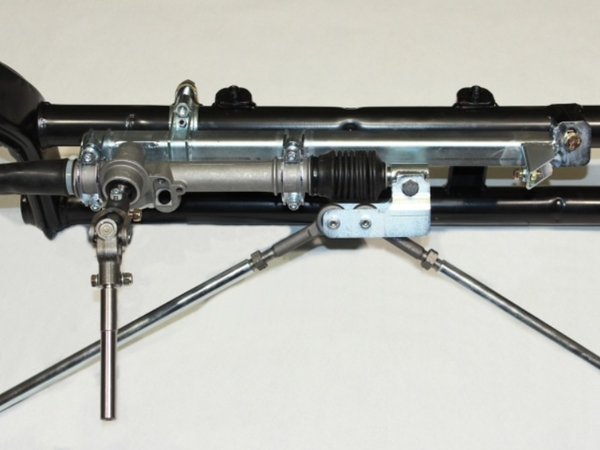

Left to right: 911 steering U-joint, custom fabricated SOLID tie rods with Polo inner tierod ends, and rack clamps to hold the rack on the rack bracket:

The rack and the rest of the hardware. L-R: 911 U-joint bolts, inner tierod bolts, beam clamp bolts, rack clamp bolts, and outer tierod ends:

The rack does indeed have a 60 spline 16mm D-shaft(R). The 911 U-joint has a 36 spline 16mm size(L):

I partially removed the splines with a 5/8" bit on one end of the 911 joint so it could slip onto the rack. The 36 splines are MUCH deeper cut than the 60:

This is the other end left alone:

It slips on, but will need to be tapped with a mallet to go all the way on:

The single 8mm bolt has a clamping force of almost 5000 pounds when torqued. I'm not worried about slippage in the least.

But just to hedge my bets, a Kia U-joint is on the way via ebay. I'll know exactly which way to go once I start to actually mount this stuff.

Also, I told Alex I had a 2" narrowed beam so the tierods should each be 1" shorter. I'll see if that was done. The tierods have right hand threads on the outers and left-hand on the inners. The locknuts are 22mm and the tierods themselves have an 18mm wrench flat on the outer end.

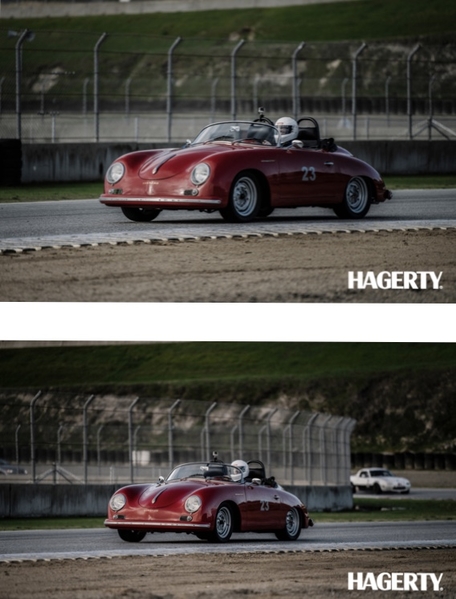

I'll take the tank out next week after the Kia U-joint arrives. That way it will be minimal down-time for the Spyder.

The rack is 3.5 turns lock-to-lock(I think my steering box is about 3 turns), and I may be installing stops on the rack bracket so my tires don't hit the wheel wells. I didn't measure the travel distance of the rack. It appears to be plenty, so 3.5 turns should be more than enough.

It's amazing how many Speedsters and Spyders don't have the steering stop bolts in the factory locations on the beam. I remember Michael commenting that the metal stop needs to be trimmed/removed.