I have moved my posts concerning the Puma I bought a few weeks ago to this forum page and have stopped posting on the Classified page that this was started on.

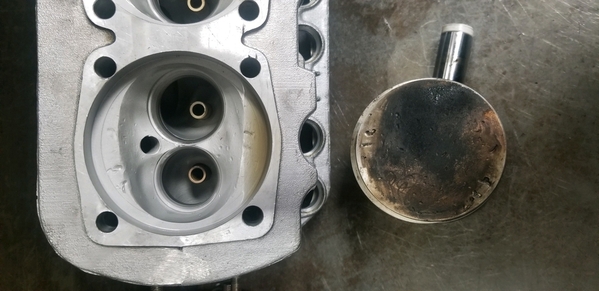

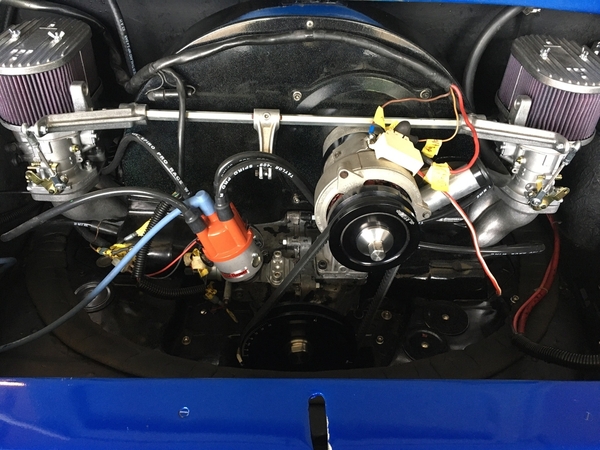

Update. I have the engine out and will drop it off at my guy Bill Westerfeld of Westerfeld Enterprises in Harrison Ohio right out of Cincinnati. He is a well kept secret and a wonderful all around great resource to go thru an engine an put right all that is wrong and make the modifications asked for. He works fast and is fair with the price. He was the head engine builder for Drews Offroad which is now the Dunebuggy warehouse before he went out on his own. Bill also rebuilds Porsche engines for street and race. He was a big builder of formula Vee race engines back in the day. Dunebuggywarhouse.com is by the way are a good source for all things classic air-cooled VW .