I had an extra piece of lower windshield rubber gasket left over from one of my installs, so I cut a small piece as a cross-section to show what's happening when we try to install the gasket on many of the cars out there and why it can be so frustrating. Usually, you get the glass installed in the lower gasket, then try to fit them both over the forward lip of the aluminum trim piece, or you fit the rubber onto the trim piece and then try to fit the glass into the rubber. Often, as the install proceeds the glass either pops out of the gasket of the gasket pops off of the trim piece. Many of us give up in disgust after an hour or so and simply push the forward edge of the gasket up against the back of the vertical trim lip and say "Good 'Nuff!" and move on.

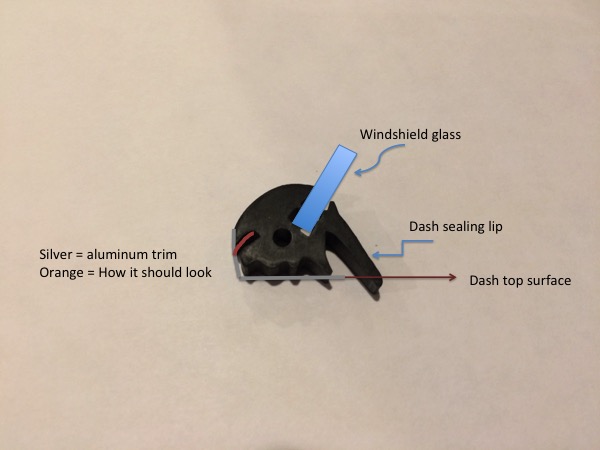

Below is a photo of the cross section, with the other components drawn in. The aluminum trim piece is attached to the cowl (usually pop-riveted) and the rubber gasket and glass is lowered down onto it with the vertical lip of the trim piece supposed to fit into a slot on the front of the rubber piece (on the left). We've all been using this same rubber gasket for years and it simply doesn't fit quite right.

The main problem is that there needs to be an additional bend in the vertical part of the trim piece to aim the lip better into the rubber gasket slot.

This photo shows what the trim piece (silver in the photo) looks like usually, with the orange line on the left showing how I believe it should be bent to better fit the gasket. I haven't (yet) done this, but since it is made of aluminum it should be easily bent with electrical pliers or a hand-held flashing bender tool - a light bead-bender would be perfect, IF the trim piece was not yet mounted to the car.

The only issue is that you're bending a vertical surface of a piece of metal angle that also has a gentle left-to-right bend to fit to the shape of the curved windshield. Resistance is to be expected, but once you get the right bend (to the proper depth) that new bend will be hidden up in the gasket, out of sight and everything should look like a factory install.

Remember that the windshield top tends to move forward or back as you complete the install and begin to tighten things down so diligence in making sure everything stays in place is still needed. Once set, the windshield should fit more-or-less evenly along the cowl, but I've noticed that pulling the back corners down to attach the top frame screws tends to rock the glass rearward allowing the bottom front edge to lift up. It's a balancing effort that takes patience to get right. Much of your success depends on the placement of the aluminum trim piece AND where the corner posts are mounted in a relationship. If they're not perfect you'll have issues or will have to compensate to get everything to fit properly.

Don't know if Alan Merklin has been doing this or not, but it just seems to make a lot of sense. I may be trying this later in the Spring on my car to correct a minor fault that I've been living since I installed my replacement glass.

Any other thoughts on this???