An open-end wrench broke, and the piece that broke off went into the engine. Of course it did, engine was upside-down on the stand. I got the piece out with lots of patience and a telescoping magnet.

A few years ago, I just had to have a twin-plug setup. I had sold myself on all the advantages, which are mostly for engines with a substantially bigger bore than the standard 94 mm Type 1, but I wanted this. Badly. And when I want something, I generally don't stop until I've accomplished it or ruined something valuable in the effort.

I had a guy make scrap metal out of a $1000 set of CB Super-Pro heads trying to machine in the second plugs. Undaunted, I started over at ground zero-- bought a set of Rev-Master 049 twin plug heads, and had them CNC ported by Rev-Master Automotive (who I'm sure subcontracted them to DRD). I got them exactly a year after I had embarked on this fools errand, and I spent another 6 months and many more thousands of dollars getting the long-block together. All that was left was dressing the engine.

It was late in the spring, too late to be doing this little project-- but I was hard at it in the garage, determined to get this thing on the road by the 4th of July.

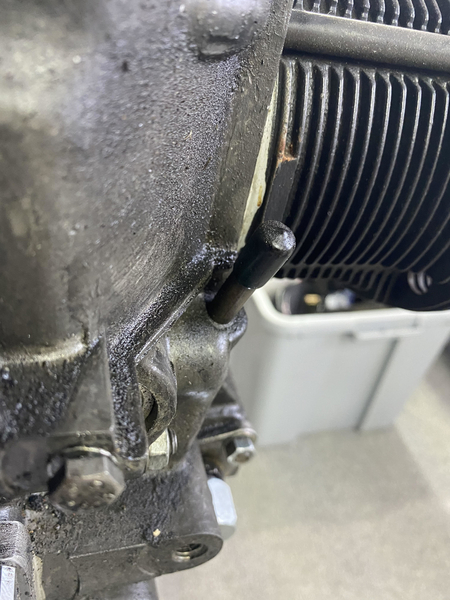

The second set of plugs in a set of 049 twin-plug heads are accessed through the rocker box. The process involves taking off the valve-covers. In the bottom of the rocker box are two little plates, and under the plates are holes where the plugs can be accessed. It's a slick set-up, and the plugs come into the chamber at a good angle (instead of being badly canted). Anyhow, the head is spot faced around the holes, and the plates seal to the head with two tiny little screws and a bit of flange sealant. It's kinda cool, if a bit Byzantine.

On this particular evening, I was running plug wires. I had the engine completely dressed otherwise, and this was the last task on the list. The engine was on the stand, and I was removing the plates to get access to the plugs. I had the 3/4 head pointed straight up so I could see everything better. I removed one screw, then the second-- and I saw it happening

i n s l o w m o t i o n.

You know what happened. We all know what happened.

I dropped one of the size very tiny screws right down a pushrod tube. It was a perfect shot, and I couldn't do it again if I was being paid for it. I could hear it rattling around as it went down the hole. It seemed to take about 30 seconds to find paydirt, and sounded like it was taking the scenic route, bouncing off everything along the way before it stopped.

I thought I was going to throw up. I contemplated suicide, looking for a hook to throw a rope over.

But I was in luck! I could see the little chunk of micro-hardware by shining a light down the pushrod tube. It was laying on the lifter, leaning against the base of the pushrod. I tried to get it with a magnet, but the screw was steel, the pushrod was steel, and the lifter was steel. There is also considerably less real estate inside a pushrod tube (with the pushrod installed) than one might suppose. I needed a cleaner shot.

I very carefully loosened the rocker adjustment like it was the detonator to a nuclear bomb, and ever so carefully pulled the pushrod up in the hope that the screw would fall into the pocket of the lifter. I was looking with the light (held in my mouth) while I gently pulled the pushrod. I lifted ever so gingerly...

... and the screw teetered on the edge of the lifter, before bouncing its way into the bowels of the engine.

My shoulders slumped. I breathed a heavy sigh. I did not yell, or swear, or rage. I just walked over to the door and shut off the light and went inside. I contemplated why I thought I was anything more than an ape with tools. I went to bed and looked at the ceiling. I pondered taking up heavy drinking. I went through the 5 stages of grief. I castigated myself for the life decisions that had brought me to that point. I decided I truly hated cars in general and this car in particular. I bargained with God. I thought of boxing up the (nearly complete) engine to be 100% torn down to find a ridiculous little piece of micro-hardware. I thought about skipping town and hitching a ride on a freight train. I contemplated hauling the whole thing in for scrap.

I pictured that screw getting sucked up the pick-up and happily grinding it's way though many thousands of dollars worth of softer metal. I envisioned the discussion I'd have with my long-suffering wife explaining why her special needs husband needed to inject another few grand into the garage art out in the shop. I pictured my father never laying eyes on my mother, and contemplated what a happy place the world would have been if they never met. I imagined the shame and anger of missing an entire season of driving-- all because I just had to be the cool kid with this twin-plug nonsense, and because I'm blessed with an ego unencumbered by intellect, fingers the size and shape of bratwurst, and a brain the size of a walnut.

About 4:30 AM, I got dressed and went back out, ready to face my Waterloo.

I slowly turned the engine to level. I rocked the engine around on the stand like I was mad at it (not that I was, or anything). I was attempting to rattle anything that might be squatting up on a lifter boss or in some other hidey-hole loose. I prayed that the Lord would grant me mercy, and somehow help me get this thing out or allow me to die in the effort.

... and then I started sweeping the entire sump with a magnet, which was no small feat considering the pickup leaves about 1/4" of space around it.

After a minute or two of graceless sweeping, none of which I was entirely sure was even touching the tip of the magnet to the bottom of the sump, I pulled out it out.

And there it was-- right on the tip, like a little beacon of love. The only thing missing was the sky opening, and the hand of God Almighty reaching out to touch my flaccid finger like Michelangelo's "Creation" scene in the Sistine Chapel. I'm pretty sure I heard angels singing, and the sun broke over the horizon at the very moment of rapture.

I was spared.

I went inside. I didn't touch one thing on the engine that morning. I made a big breakfast, I went to work. I lived to fight another day.

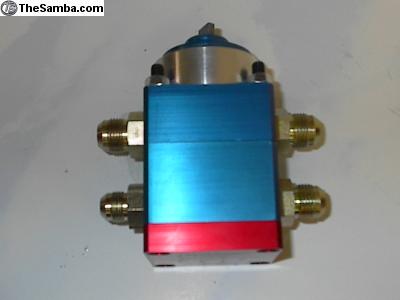

A lot of people have asked me the details about my speedster so I thought I would start a new thread. Let me start with a disclaimer: this is what I have found that works well through my experience

A lot of people have asked me the details about my speedster so I thought I would start a new thread. Let me start with a disclaimer: this is what I have found that works well through my experience