Anyone have a suggestion for plug gap? I'm running .24 but a hotrod friend I trust suggested .28. Do you guys have A LOT of trouble removing these plugs from a IM? I reloved even the intake manifold to find out what the damn problem was. It's the way the metal baffle is cut, right?

Replies sorted oldest to newest

Yeah, the plugs are a PITA to get at. Have a combination of plug sockets and different length ratchet extensions handy. One of those swivel-foot extensions at the socket is handy, too.

Setting your plugs ar .024" is kind-of tight. I would go with .028" too.

Bosch small cap distributor and regular coil (what you have)- gap at .028". Any wider and they will misfire under certain conditions. Most electronic ignitions- pertronix, Compufire, replace points with electronic parts, don't increase spark power and will use a similar gap. Not until your ignition actually creates a stronger spark (more powerful coil and/or ignition box) can you increase plug gap, and now you can get problems with misfiring in the distributor cap itself because the contacts are so close together. This is why the higher end distributors use a bigger (wider) cap.

A shortened/contoured spark plug socket and 'wobbly' extension (doesn't have as much movement as a universal joint but is much more compact) will make plug re&re much easier.

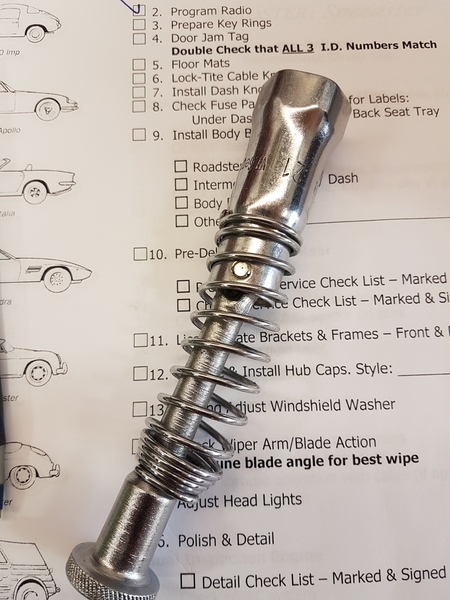

As well as shortening your spark plug socket (I was able to take 1/2" off mine), a little grinding work around the top will help clear the intake manifold easier. If your plug socket has a rubber inner to help hold the plug, pull it out and cut it down as well. I don't have a pic handy of the spark plug socket, but you'll get the idea from the socket below-

Hope this helps. Al

PS- just had a thought- do any of the tool companies make spark plug sockets in 1/4" drive? Just the ratchet being smaller would be really helpful!

Attachments

Thank you! My cap and dist. is Toyota. I'll check that.

IMs have used CB Performance Type 1 longblocks for years, then dressed them themselves up in Vancouver. I've never had any issues getting the plugs out, but my setup was supplied by me, not by CB or IM. If you are having issues, it's probably a result of interference between the intake manifolds and/or the cylinder tin. There are no shortage of intake manifolds that need a little bit of grinding to allow a plug wrench on the plugs, and the tin is a one size fits all proposition that (in truth) generally fits a stock engine pretty well and needs a bit of tweaking to work with anything bigger. If you need to open up the tin, you'll probably need the engine on the floor. The intake can be removed and ground, if that's where the interference is.

I can almost guarantee that your engine came to IM with the plugs in, and that they installed the intake, tin, and plug wires afterwards. Their plug socket might have been thinner walled than anything you've got. You mentioned needing to drop the engine to replace the plugs before. If that was the case, and you are still having problems-- then your mechanic was also part of the problem. It's not a big deal, once everything is out in the open to make it all work nicely. No remove the tin or intake, replace the plugs, and just put it back together without fixing the interference issue is lazy. I'd personally have a bigger issue with an ongoing problem perpetuated by a mechanic without the initiative to fix the problem than an initial (and understandable) problem from the builder.

If this were me, I'd grind a socket down as thin as it can get, and try again. I've done this before. Most plug sockets are enormously thick. If you can't move the mountain, move Mohammed. If this won't do it, you'll need to follow the instructions in the above paragraph.

Your plug gap is going to be a factor of a lot of different things. You've got the CB MagnaSpark and a Bosch coil. The gap with that setup is going to be different than if you had a CDI box or some hotter spark. Your wires will also factor into this-- are they 7mm resistance wires or 8mm copper core? They could also be 8mm resistance wires and plugs, so look at the jacket (and the plugs) to see. I would assume they are 8mm resistance wires and resistance plugs. If that's the case, .028 would be a safe maximum. .024 would work too, if everything else is right. Look at the plugs when they come out-- chocolate brown is perfect, and I wouldn't change a thing. Black but not sooty is generally OK too, as most people set up the jetting a bit rich. Black and sooty (or worse, wet) means you need to be jetted leaner or get a hotter spark, or both.

Good luck. Forewarned is forearmed.

This "problem" is far from exclusive to IM. As Stan pointed out, a LOT of people use CB engines. Any performance engine from anybody is going to have issues with getting to the plugs, especially the rear ones. I'd go so far as to state that ANY engine equipped with a one carb throat per barrel setup is going to have a problem here.

It's just the way it is when you take a basic economy car and triple the horsepower.

Stan is right and my mistake- that isn't a Bosch but a Magnaspark distributor. Because of the bigger cap spacing, if you feel ambitious you could try .030" for plug gaps and see if the plugs will fire reliably (the biggest spark possible will give the cleanest burn-I've heard of guys trying it but never heard of the results), or just set them at .028" and be done with it.

If the upper cylinder sheet metal doesn't actually interfere with the manifolds seating properly I would leave them alone. Changing plugs with dual Webers or Dellortos is a pain in the a**, but you do get better at it after a while. The cut down/clearanced plug socket and wobble fitting make it much easier. As Danny said, it doesn't matter who made your car- changing plugs is difficult in all of them. Dual carbs in a Beetle are no different.

Stan, I'm the ONLY mechanic, but I'm not a mechanic. As I think you know, once I removed the rubber hose dropped into an inlet by IM, the engine was a different beast. It runs great now, but I think it might need a bigger spark since I'm still, on occasion, getting a bit of unburnt fuel hitting the exhaust. After my engine fire, I completely rebuilt the 44mm Webers, transferring everything into new bodies, even the venturys. How do you spell that? The pipe-like things above each inlet. NOT easy to get out. My exhaust.

Attachments

Henry had me buy some $100 tool to get the plugs out. It wasn't even the correct socket size which is 18mm for my plugs.

I used to have one of these that came with my '72 914. No ratchet but multiple hole for handle. These were for the old larger plugs not the smaller plugs.

One of these Hazet tools would be handy -

Attachments

o 2110cc High Performance engine with CB Performance “round port” CNC ported cylinder heads, dual 44mm

IDF Weber carburetors, CB Unitech connecting rods,

1 1⁄2” heat exchangers, IM custom 2 1⁄2” diameter exhaust (requires breakerless high performance ignition, rotary

electric fuel pump, special full flow oil cooler, 72 plate)

145 hp @ 5500 rpm; 142 ft-lbs of torque @ 4800rpm [See ‘Special Instructions’ section]

o Custom carburetor tuning 550 o Rotary electric fuel pump 195 o Special full flow oil cooler, 72 plate, with power fan and 610

automatic temperature switch, all stainless steel hoses

o Ceramic coated exhaust system, bright silver. 615

Exhaust through bumper guard with original funnel, dual Magnaflow “straight through” mufflers for more “Sporting” exhaust note

ALB posted:Venturi

And @DannyP- the rear ones are easy- it's the front (of car) plugs that are hard to get to

Al, rear as in farther away from the spark plug changer. Poopiehead!

Wolfgang: that Hazet tool is nice but it isn't 18mm. 18mm long reach is the standard spark plug used in ALL CB Performance "high-performance" heads. They use 12mm threads instead of the standard VW/Porsche 14mm short reach plugs with 13/16" socket size.

I've found that it is not necessary to grind an 18mm thin-wall six point Craftsman socket, 3/8" drive. It may/probably be necessary to grind the much larger 13/16" socket.

I had welded manifolds on the CPR 2332 when it was back there. I was able to get the plugs out with a 12 pt Craftsman 18 mm socket, but it needed to be ground almost paper-thin.

As far as pulling the plugs, I have a cmc built by someone else, I haven't changed my plugs but have noticed the builder used a hole saw and cut four holes right at the plugs. He then made four black plastic plugs that plug into the holes, I assume these holes will make my life a little easier when the time comes, has anyone else ever done/seen this ? the plugs he made are basically invisible.

Darrell

widebody boy posted:As far as pulling the plugs, I have a cmc built by someone else, I haven't changed my plugs but have noticed the builder used a hole saw and cut four holes right at the plugs. He then made four black plastic plugs that plug into the holes, I assume these holes will make my life a little easier when the time comes, has anyone else ever done/seen this ? the plugs he made are basically invisible.

Darrell

I've only seen retrofitted "ports" or access plates on VWs equipped with dual throat carbs such as Weber/Dellorto to access them for adjustment. Those are also a pain in the ass to adjust in terms of accessibility.

Your engine sounds like my 2110cc CBPerf in my 2004 IM. with 44 IDE Webers. Pat Downs and his help are pretty good at giving you info on your particular engine if you want a neigh from the horses mouth. I had that engine for 5 years. Great engine.

OK, I'm confused.

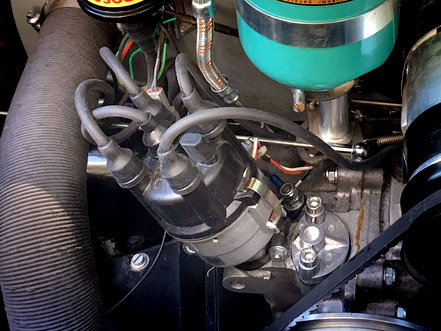

Here's Eric's dizzy:

This looks very different from my Magnaspark II :

The cap is held on with clamps, not screws, the wires use a different type of connector, and the cap looks to be smaller in diameter than my Magnaspark. Did they make an earlier version that looked more like a Bosch dizzy?

Attachments

Here is the damn tool Henry insisted I buy for $100. Fits nothing I know of. How could Henry not know what tool fits his plugs?

Attachments

I was speculating on the distributor make. I have no idea what Eric has. I saw the big cap, and assumed. You know what they say about assuming...

Attachments

I wouldn't know without pulling one and measuring the disti shaft OD, but if it is a Toyota it's probably similar to that from the 18RC engine series, as Toyota used it on a lot of engines until they went with the HEI version (wider cap). It would be a handy point of info if there is a number or tag on it to identify it for those who might want to use one on a VW engine. It would also be interesting to know what the advance curve looks like, just for yucks.

@Impala Darrel: Several on here have cut small ports into the inner wheel well liners for better access to the plugs. Typically, they fit some sort of water-proof boat access cover for ease of use later on. Those are both round and oblong - whatever you think fits. Try West Marine. Try searching on "Hatch".

I haven't heard of ports like that being installed likewise for the carburetor adjustments. I found a small tool at Lowes that makes carb adjustment a lot easier, whether you have a flat screwdriver slot or a hex head adjuster. Lowes SKU 337335 magnetic driver and it's under five bucks. This version does not ratchet and accepts a 1/4" square or hex drive bit so you can easily get it onto the carb bits with plenty of clearance.

https://www.lowes.com/pd/Kobal...river-Set/1000566887

Personally, I have not seen the need for any special tools to get the plugs changed beyond a 3/8" ratchet, magnetic plug socket and a 2" or less extension. True, they're a PITA to get at, but they CAN be gotten at. OTOH, I've tried to use one of those Hazet plug tools (In a tool kit on a 912) that Wolfgang showed, and it was impossible to get the plug loosened using that little T-handle - simply not enough leverage on a plug that had been in there for a few years. Give me a good old 3/8" ratchet any time.

Attachments

thats exactly what somebody did, the holes are cut into the inner wheelwell and have black plasic plugs, roughly 3 inches in diameter, its gotta help when I change the plugs, from where they are, it looks like a straight shot to the plug.

widebody boy posted:thats exactly what somebody did, the holes are cut into the inner wheelwell and have black plasic plugs, roughly 3 inches in diameter, its gotta help when I change the plugs, from where they are, it looks like a straight shot to the plug.

Any chance you have a photo of that modification?

My engine is a 1904 built with CB Performance parts, dual baby Webers and Flamethrower II ignition parts and wires. The engine and heads were assembled by a guy whose well known in the Porsche world for doing heads for race cars and Harleys and my valves are bigger, so I don't know if this applies to your engine. But, anyway, he has me set my plug gap at .030 and the car runs great. ( sorry, but the build sheet and specs are 1500 miles away)

I do my major maintenance in the spring, so the car is on jack stands with the wheels off for easy access to everything. I have installed a 4" removable access cover opposite the 1 and 3 spark plugs ( front, back, whatever, Yoda and Danny) and I can actually see the plugs. With a long extension and a ground down socket I can get to those buggers with ease through the wheel well.

I'm not as flexible as I used to be so this works for me. Best of luck.

Al, thanks so much! If I can't get the plugs easily, I can always take off the Webers and inlet AGAIN! I've done too much wrenching in my life and just want to DRIVE now.