Replies sorted oldest to newest

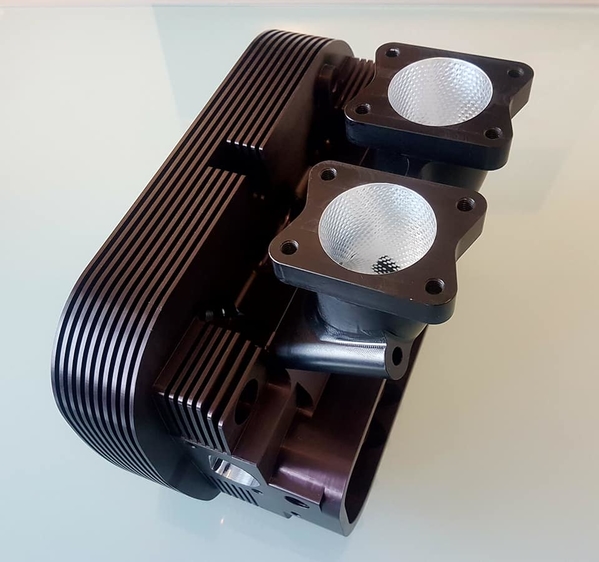

DANG! That is awesome. ![]()

I'll bet they are designed for drag racing, and not much good at anything else.

They are nice.

It appears as though the head is machined from a solid billet with the intake manifold from another billet....... Still beautiful work and probably really, really pricy...

LeonChupp posted:It appears as though the head is machined from a solid billet with the intake manifold from another billet....... Still beautiful work and probably really, really pricy...

Yes, beautiful work.

As has already been said, very cool and (I'll bet) very pricey! Any other pics? Is it a type 1 head? valve and cylinder bore sizes?

PS- I'd love to know how they did the golf ball dimpling..

I'm not Bill, but here are some links

http://www.ng-motorsports.de/?lang=en

https://www.facebook.com/pg/ng...s/?ref=page_internal

Forgot to say, I've heard them, called Golf Ball intakes.

Dimpling was probably done with an internal Knurling wheel....or some hot dogger has a hell of a CNC program....

Its probably for a type 1 (exhaust ports).... The local type 4 builder here in Ga. (Danny knows who I mean) did a set of type 4 heads with type 1 exhaust port locations....

LeonChupp posted:Dimpling was probably done with an internal Knurling wheel....or some hot dogger has a hell of a CNC program....

Its probably for a type 1 (exhaust ports).... The local type 4 builder here in Ga. (Danny knows who I mean) did a set of type 4 heads with type 1 exhaust port locations....

Machinists are the unsung geniuses of the modern age. To do that would be astoundingly difficult.

Stan Galat posted:Machinists are the unsung geniuses of the modern age. To do that would be astoundingly difficult.

And sadly, those are skills that are being lost these days. We really need more emphasis on skilled trades and quality apprenticeship programs for younger people. Unfortunately, what we are getting are more unemployable university graduates.

Trades training was always an emphasis of mine when I worked in the college system here (after leaving the university system, where I became increasingly exasperated at what I saw).

Bob: IM S6 posted:And sadly, those are skills that are being lost these days. We really need more emphasis on skilled trades and quality apprenticeship programs for younger people. Unfortunately, what we are getting are more unemployable university graduates.

Trades training was always an emphasis of mine when I worked in the college system here (after leaving the university system, where I became increasingly exasperated at what I saw).

My dad was a Renaissance Man.

He was the twelfth of 16 kids. His dad emigrated from Serbia when he was a boy, and was a butcher and grocer. Dad grew up in the meat market, cutting pork and beef. When he was a young man, he rebuilt the engine in his Pontiac by taking it apart and buying new parts for the stuff that looked worn.

His older brother was a contractor, and dad worked for him when he got out of the army. They were old school carpenters and did everything from concrete and block-laying to roofing themselves. Dad was expected to tag along when the subcontractors were doing the plumbing, heating, and electrical.

The pluming contractor needed help one day, and dad was hired by that evening. He apprenticed under the guy until he hung his own plumbing, heating, and electrical shingle out in 1966, when he was 27.

He moved us from Akron, OH to Nowhere, IL in 1968, so I could grow up in the country. He built the home I grew up in after work, every evening for 2 years. He worked out of the union hall on a power-plant going up in the early 70s, hated it and hung his own shingle out again. In the meantime he built 2 ranch houses for spec.

His plumbing business took off, and through the 70s he was plumbing 50 houses/yr. I was expected to be there with him when I wasn't in school. I spent every summer in my youth digging ditches and cutting and reaming pipe. Dad took progressively bigger jobs, until he was doing some municipal water/sewer projects. He built a fish hatchery in southern Illinois. He built a sewage treatment plant for a small town south of here.

He built "the house" (the one every middle-aged tradesman wishes he'd raised his family in) just about the time we were grown. It was a hole in the ground when the bottom dropped out in the 80s. He continued building the house, burning through the capital he'd accumulated during the fat years. We pulled stones out of the creek behind the house to lay up the 30 ft fireplace/chimney. He had a 40x80 barn out back housing his business, where I stored my (growing) pile of cars and parts.

He started doing heavy commercial plumbing (the only thing going at the time) while I worked at a Mobil service station in town. He made freakish money doing it, and was an incredible stock-market investor. We tried to work together one more time (for a year) but by the time I was 20, I knew I had to make my own way. Eventually, I started my own business, and did pretty well-- but If I'd have just stayed with Pop, I could have retired 10 years ago.

He did volunteer work, and remodeled my home. He built a duplex for my sister, and started taking remodel projects. He learned to program, back in the DOS days. He worked with the South Side Mission to remodel bathrooms for people who couldn't afford it. He built my "big house" (the one I wished I'd raised my kids in) and a 30x40 barn out back, housing my business and car junk.

The point of this? Dad (and I) worked for somebody else maybe 15 years between us. Neither of us went to college, and both of us found success (to one degree or another) in the skilled trades. Everybody I know who took this route has the same story, to a greater or lesser extent. It hasn't been easy, but it's been a really good life.

I'm not sure why it was decided 20+ years ago to do away with shop classes in high-school, but it was a mistake. Nobody learned everything they needed to know back there, but shop classes were a stepping stone into figuring out how stuff works, and going from there. We welded, ran machine tools, and did fine carpentry. I had no idea how to troubleshoot an electrical problem-- but I learned how electric worked, and took it from there.

Trade schools (in this neck of the woods) are a joke, teaching kids how to rip people off. It's apprenticeships that this country needs, and the best place to find a real one is at the local union hall. There are a lot of things wrong with unions, but there's a lot that really does work. Full scale for a union steamfitter is nearly $50/hr, with an additional $15/hr in benefits. It's a fantastic life, if a guy is willing to be cold and wet, and if he is willing to have college-educated shoe salesmen look down their noses at him.

I know I'm foaming at the mouth. It's just hard not to.

Well said. I went the college route before and after the Marine Corps. during the Viet Nam years. I wish I had augmented my formal education with more shop classes in High School and maybe picked up some welding and electrical experience along the way, but I was probably too full of myself and too busy back then. Mostly retired now with the desire, and some time, to do a few more "hands on" projects, I find myself without the skills I wish I had picked up along the way. I am considering the community college for some classes. One thing, I will probably be the most "seasoned" student in the classes.

I did just sit for and pass the Real Estate Associates State Licensing Test yesterday so that I can help my wife out in her business. The process of learning all the dry ingredients that go into the business has sparked that desire again to stretch my nearly 69 year old brain to learn more about a number of other things.

My body can't do what it once did, but I think my brain is still reasonably pliable and absorbent.

I started taking wood shop classes in the mid 70's when I was in junior high. In high school I took four more years of wood shop classes. I also took one year of ag related mechanics which taught us to arc weld, mig and tig weld, and cut and thread our own nuts and bolts. I also managed to fit in a couple years of small engine repair classes.

I've been a firm believer for a long time that this failed idea of getting everyone prepared for college has made a nation of people that are unprepared for life. I hate using the term "kids today" but there is no other way to say it, kids today are wholly unprepared for life since they do not have the opportunity to learn from a more well rounded curriculum. I didn't become a mechanic, welder, or craftsman of fine wood products. But I'm not afraid of any of these tasks. I do wish I had had more experience and taken those trades a little further.

I'm a couple years from retirement and I'll be 55. Too young to not work but too old to do the work I'm doing. I plan to start my own part-time business and I also want to take classes at the community college so I can rekindle and refine some of those trade skills I learned a long time ago so I can have a hobby to keep me busy.

Good for you, Robert! Can't chase bad guys forever.

You can make your own signs that read... "Get off my lawn..."

For some reason our society has decided to inculcate our youth with the idea that skill with ones hands and willingness to perform physical labor is to be looked down on relative to “book learnin’“. While I chose a career based on “book learnin’”, I chose one that required some of the same creative and problem-solving skills as those required to be a successful tradesman. I often think I would have achieved as much satisfaction, perhaps more, from a career in the trades. Judging a career by how clean it keeps your fingernails is stupid.

I think the Germans have the right idea with their apprenticeship program.

In Jr. High, we had a "wood shop" unit and a "metals shop" unit. Everybody took it, regardless of academic inclination.

In wood shop, we built little curio stands in the 7th grade, and turned compote bowls on the lathe in 8th. In metals shop, we built a sheet-metal tool box in the 7th grade, and had a more complicated welding project in the 8th. My dad still had the tool box in his truck when he died last month.

By high-school, we were turning out some serious stuff. We were turning and knurling stuff on the metal-lathes (bongs, in no small number), and stick-welding weight benches and other what-not. "Small Engines" graduated to "Engine Testing", etc. We had no idea we were learning anything, but everybody did.

It wasn't perfect. There was way too much emphasis on cabinetmaking, and nowhere near enough on framing. We learned to draft, just as computer programs were making drafting a lost art. We got nothing in the way of electrical, or plumbing, or HVAC. Engine Testing consisted of a bunch of gearheads sitting on their hoods eating Dolly Madison Donettes second hour, every day.

The whole thing withered and died around the millennium. The school I went to converted the wood shop into a weight room, and then back to an "Ag Lab" where they learn to weld and frame. The metal shop was the maintenance office until the robotics team took it over.

... giving me hope for America. Tremont High School has fielded a top-flight robotics team for several years, and they were world champions last year. The whole thing is run by volunteer Caterpillar engineers, teaching a bunch of gearheads how to build something from off-the-shelf parts. When my kids were in school, it was all "college prep this-n-that", and very little hands-on practical engineering. We've got that now, at least in a town with 2000 people on the rim of nowhere.

My mother's side of the family have been here farming and building canals since revolutionary times.

My grandfather had a third grade education and went to work right after that. He did many jobs including making felt hats and a railroad cop. Still have the hat!

He designed and built the house I ended up purchasing in 2007 in the 1950s. I love it and appreciate every nail and screw driven by him. Poured the foundation and laid the concrete block.

Apprenticeship? His was called life. My mom says I move just like him. And apparently he was a do-it-yourself guy so I inherited that. Been taking things apart and putting them back together since I was three. I'm a tinkerer. Can't help it. Learned electronic soldering at 10, sweating pipes at 11. Thanks to Dad for both! Learned auto mechanics on my own and worked at a shop for a couple years.

Somehow I meandered into the telecom trade and went to work for New York Telephone in 1991 at 27. I'll be 55 next year with 28 years of service and am leaning hard toward retirement. It took 5 years of working to be competent enough not to kill myself or anyone else i work with. 10 years to be good at my craft. 15 years to be able to build and troubleshoot any equipment the telco has.

There is nothing to be ashamed of by working with your hands. I'm enjoying a good life from my labor and should be able to carry that into retirement.

I absolutely can't stand paying someone else to do something I can do, which I've found is almost anything. I just pulled my girfriend's Subaru engine and did the head gaskets. I'm sure I saved about $1000.

I'm seriously thinking of building Spyders for a living, because like Robert, I'm too young to retire but too old to start a whole new career.

Stan just brought up an interesting point. Robotics marries the flavor of the moment (computers/software) with mechanics, and would have been perfect for me had it been a thing when I was young. It has a chance to bring "sexy" to a form of mechanical labor. Fingers crossed that it does so.

Danny also brings up an interesting point. Here is a fellow who chose a trade over a while collar career. He is seriously thinking about retiring in his mid 50's. On the other hand, I, who chose a fancy-shmancy white collar job in the software bidness, will probably not feel safe retiring until I'm close to 70, which is still 8 years off. I'll do fine, but I won't be rich. This is the difference between a career path that offers a pension versus one that doesn't - as most high-tech jobs don't. I don't regret my choice as it has suited me and treated me pretty well, but it included some negatives that I was not aware of in the beginning.

Choosing a career is one of those decisions that school guidance counselors and college advisors are supposed to help you with, but they usually don't have enough experience of their own to do so. This should be a class that all high-school seniors are required to take, along with personal finance.

Trade schools (in this neck of the woods) are a joke, teaching kids how to rip people off.

I'd like to hear that story, Stan.

As for the rest of it, dittos. Grand dad built his own house. Uncles Pete and Bib did the same. And by "built" I mean just that. Dug the holes, capped the chimney, everything in between.

I grew up watching men build stuff and work on stuff and transform stuff as a matter of routine (there was a Buick or something like one that became a boat trailer—for the cabin cruiser Pete built—over the course of a weekend). Other dads went to ball games or coached soccer. We went fishing in Pete's boat, and swung hammers.

Lane you are very right. Imagine if we had computers, servos, robotics to go along with the Erector sets we had? The things I would have built.......but wait until you see my CHT x 4 display, complete with robotic disappearing act.

I didn't really choose my career, it found me. Right place/time situation.

There should be way more taught in school of the practical. Change a tire. Do laundry. Cook. Apply for a loan, and what collateral is. The list is endless.

I wish I took typing!

“I wish I took typing!”

Me too, Danny. Me too.

Wow. Terrific stories from all of you.

I did take typing! And then I started writing software and learned how to type real fast! My favorite key in those early days was “delete”!

I grew up on a farm and was always considered “the bright one”. Didn’t know what that meant for a long, long time but, like some of you, took the woodworking and metalworking classes in jr. and sr. high school but was always one of those in the “advanced college prep” courses as well, where I did well, but was perpetually bored. I wasn’t into, nor did I have time for, major sports but pretty much worked for my Dad since I was ten or twelve years old.

Since most farmers eat well but are otherwise poor, I learned to fix stuff, starting with farm equipment, then those big, console radios everyone had back then, then pretty much anything. Had my first Ham Radio license and built my first radio station at ten years old, was writing magazine articles for high performance short-wave antennas at fifteen. I was also my Dad’s “head mechanic” for his fleet of school buses, doing everything from oil changes to tune ups to brakes (we let the professional shops do major engine/transmission repairs, usually under warranty).

All those years growing up, I was friendly with the “motorheads” as well as the college-bound and was, as far as I know, the only person bridging the gap between those two groups. One good friend graduated first in our high school class and got a full Navy scholarship to Harvard through his Doctorate and ended up running the Anti-Submarine Warfare effort in the Atlantic for the Navy. Another good friend (and stellar Hot Rod builder) barely made it through high school but was the nicest guy you ever met. He got a job working in a liquor store and later opened one of the first liquor super markets in the Northeast, expanding over ten years to six huge stores. He sold them all in the past three years and has made millions. He now lives on Cape Cod and drives one of the prettiest 35 Ford coupes I’ve ever seen.

Another motorhead friend worked in his father’s gas station, went to Viet Nam, lost half a leg and returned to take over his Dad’s business and just retired last Fall. He is the only guy from high school who has ridden in both my Dune Buggy and my Speedster. His only comment after exiting the Speedster was “you shoulda had THIS engine in your friggin Buggy!”

As some of you know, my son has taken very much after me in his life and career, and most of his close friends are motorheads, but not all. They all just predate millenials but not all went to college. What they all share is a desire to make something of themselves on their own terms with their own skills and are willing to work hard to get there.

My daughter, whom none of you have ever met, works at an engineering university nearby, sort of a smaller (and competing) version of MIT ( it’s WPI.edu ). She sees and works with Millenials all the time - they have an enormous outreach program sending students all over the world to work on real, meaningful projects and while you wouldn’t think that engineering students would need (or want) real-world skills, those skills are offered to them (it was called “Grunge Lab” when my wife went there) and they are very much encouraged to take advantage of them because the faculty believe that it is important that they understand how to create what they can envision to enable them to work more closely with those actually making their stuff. They are really making a difference out there on a daily basis.

Me? Yes I went to college, but ia lived at home after a while and continued to work for my Dad along the way. I’ve always had a weird job. I was what’s known as a project manager in a matrix-management environment. Nobody technically worked directly for me, but they were kind-of “on loan” for the duration of the project. In that regard, I had the responsibility of a Senior VP to get the project done, while having the line authority of a Janitor. In order to effectively manage in that environment, I needed to understand everyone’s job as well as they did so that (a.) I could coordinate their efforts in concert with everyone else to a common goal, (b.) I could get them involved with the right people at the right time for both to be as effective as possible (and keep everyone else away from them so they weren’t distracted) and (c.) If I knew their job as well as they did, they couldn’t BS me when things got frantic.

I worked with all levels of people from the guys and gals in shipping/receiving all the way up to the founder/CEO. Talk about wearing a lot of hats! The one thing I really learned is that everyone, at all levels, usually just wants to do their job as best they can and feel good about it. Tell them what you want done, find out what they need to do it, get that for them and then turn them loose and see what they do while running interference for them if they need it so they’ll be a success. That’s all they want. And maybe free coffee. Some people totally blew me away with their efforts. Others didn’t but tried really hard along the way. Some of them had been to college, others had barely made it through high school and became successes in spite of everything......All it took was some encouragement at the right moments along the way.

In the end, other than learning about life and people in a medical group in Central America as a teenager, I don’t know where I got my abilities from, but would strongly suspect good parents, a few good teachers, and a couple of very strong and courageous mentors along the way whom I didn’t even recognize as mentors until they were gone from my life. They saw something in me and gave me that little nudge here and there that made all the difference. That stuck. That is what I have tried to do with other people along the way. Some collegues griped that I was too “hands off” as a manager, but those on my teams who “got it” realized that I was there for guidance, support and air coverage from hostile elements - the rest was up to them and only they could make them a success. I was that guy that people were conniving how to get on my projects because they knew they would work hard, have fun, make a meaningful difference and be recognized for their efforts. That’s all people really want, in the end, isn’t it?

edsnova posted:Trade schools (in this neck of the woods) are a joke, teaching kids how to rip people off.

I'd like to hear that story, Stan.

It's all about the scam that has become the student loan business. I'm not sure what it takes to be eligible for students to be able to get a loan for your school, but whatever it is, it isn't enough.

Our local community college does a bang-up job with HVAC training (and most everything else). But the ICC program is long (2 years), and the classes are all at night. IT takes a lot to get through it, and most guys that are taking the classes are doing something else to get by while enrolled.

Enter the "for profit" trade school, taking classes of 30-40 people every six weeks. The "students" go through a 6 month program, whereby they are told they can make a jillion dollars a year and that the industry standard mark-up on parts is in the 500% range. They're taught to condemn any piece of equipment over 10 years old. I'm not sure any of them can fix anything when they get done. The success rate of graduates getting placed in service companies is in the single digit percentile. This "program" costs in excess of $30K, almost all of it paid for with student loans.

A union apprenticeship is 5 years-- and that's two nights a week in class, 9 months a year in addition to working 40 hrs in the trade. If a contractor doesn't like an apprentice, he can send him back to the hall. Apprentices that are unemployed end up fixing the problem, or moving on. Guys that finish the apprenticeship are worth the money they get paid. The trade school is promising those wages for a 6 month training commitment, and the graduates aren't ready to run parts for a company, let alone get thrown into a truck.

It's a scam, and it needs to be shut down.

Very interesting reads from all of you. I am particularly a proponent of apprenticeships as well. I went through a lot of schools too. Grade School , Junior High, Reform School. Didn't finish High school and joined the Navy and got more schools.Aviation Electrician School, Instrument School, ABC Warfare School, Helicopter Electrical School, NavCad School and flunked out again and finally, the School of Hard knocks. Got into a Mechanic Apprenticeship for 4 years. Had to work 40 hrs a week and maintain a "C' average at Junior College as a condition of employment. Got my first AS degree. Finished that. Got bored after a few years and signed up for LA County Sheriff Dept. Back to school. Hated the job and quit. Stayed with the County and worked my way up to Fleet manager and back to school at Pepperdine U. BSM in Management. Back to school at UCLA to learn how to teach. Taught part-time at various Community Colleges in the LA Area (Mechanics) and US History at South Gate High school.The County paid all my tuition and books for the stint at Pepperdine. I quit and went to work for the City Of Pasadena as Fleet Administrator. Went back to school at University of La Verne for MS in Public Administration but retired before I finished. Started a SCUBA Diving business and back to school to learn how to teach SCUBA. Now I'm retired and bored so I manufacture accessories for Speedsters when I'm not diving or fishing or woodworking.

I started out hating school but by the time I was an adult I had learned the value of it and an appreciation of getting quality on-job-training along with it. At some point along the way (about 1981) I re-wrote and updated The California State Apprenticeship Standards for the Division of Apprentice Standards, Mechanic Apprentice program. Since then it's pretty much been scrapped (no money) and that's really sad. The people in charge have no idea how badly they have mortgaged the future skills of that profession.

My hobby is fine wood working. It didn't start out that way though. I only had basic hand tools. To try and keep me out of trouble as a kid I had an adult benefactor who gave me an 8" table saw, a 36" lathe, and a 4" jointer. I was only 12 at the time. By the time I was old enough to get into wood shop I was ready. The teacher was shocked when he read what I wrote down as my first project on the first day of class. Most kids didn't know what they wanted to make so they got to make cutting boards for their Mother. I wanted to build an 8 foot hydroplane boat. Needless to say I didn't get to build it the first semester but I did the next once the teacher observed my skill set and knew what tools I had at home in the basement. Since then I have sold and/or displayed some of my work in Guild Shows and other venues. It is my real passion....wood.....but I like other stuff too and really appreciate skill and craftsmanship no matter what craft. I really enjoy talking to others about what they are making/doing. It's one of the things I enjoy most on this site too.....Here Endith my book........Bruce

PS here's a photo of my personal Nautical Desk, Chair, and Ships Wheel. I made the wheel but the Binnacle came off the Akibisan Maru, a Japanese Freighter sunk in 1944 just off Kwajalien Island

Attachments

Magnificent work, Bruce!

I enjoyed each and every story posted here.

What an interesting and varied group on this site. ![]()

Interesting stories, guys! And I learned something today, Bruce, as I'm not a sea faring guy and had to look up binnacle. Just got up and know a new word already; it's going to be a good day! Al

I don't know where the post went, but Dave Stroud asked: "But sometime in an earlier post about those years during that Hi tech excursion did mention that you actually gained weight up to 300 lbs ? How did you manage to lose it ? "

Almost, but not quite - I peaked out at 271-1/2 pounds during an illness and that, on a 5'6" frame, made me look like "Benny the Ball" from "Top Cat".

My illness got slowly better, I gave up the Pizzas and Queso and chips, I started walking, then walked a lot, then back on my bike and rode a lot and the pounds came off.

12 years later, my wonderful Matrix-Management job gave me stress-induced Ulcerative Colitis and I went the other way - couldn't keep anything in and couldn't keep the weight on. My wife threw me in the hospital when I hit 130 ( I was actually 128) and I lived on Meds, chicken, fish and Ensure til I healed. Eventually went back to work but totally changed my environment to reduce stress and just had fun for the next 6 years and then retired early before the placed killed me. I loved my job in the earlier years, but the pressure was intense and unrelenting and I subconsciously internalized it. Not good, but at least I could later see the symptoms in others and coach them around it.

After I had retired for a few years, I had creeped back up to 176 (that great "Southern Cooking" got me) and decided enough was enough, so I changed to a Mediterranean diet (used "The Plan" by Lynn-Genet Recitas as a guide) and went back on the bike to 150+ miles per week. Now I am usually around 155 and hold it there in the winter by riding a bike trainer indoors while watching bicycling videos of rides around the world - Yesterday I was riding a stage of the tour de France from 6 years ago near Mont Ventoux. Today I hope to get out on real roads!

That's about it!

OBTW: That diet and learning about a few food allergies really paid off, along with the regular bike riding. I found out 3 years ago that there was no longer any indication of my Ulcerative Colitis down to the microscopic level - I became a (very) minor celebrity at the UMASS Gastro Enterology unit for a couple of days for having beat it. Whoo-Hoo! ![]()

Attachments

Great thread.

[Looks at Bruce's woodwork]

Man, I am such a hack.

Hey keep the stories coming ![]()

Al...Yup Binnacle...sorta. This one had a helm wheel attached. This Binnacle/Helm was not in the"wheel house". It was mounted at the very end of the stern outside, on deck.

In the event that the Helm up in the "wheel house" or Bridge broke or failed to respond for some reason, this unit was directly connected to the rudder mechanically.

Inside this unit was a shaft coming up from a bunch or other gear reduction arrangements and terminated with a side gear. This side gear mated with one on the shaft turned by the helm wheel I made. This was a totally mechanical/manual back-up system. Hence, they needed to have a compass in it as well. I didn't remove it but I have photos of it before and when it first was brought up. It was covered with barnacles and other marine growth but cleaned up really nice. Restoring the compass and related binnacle cover/kerosene lamp is another story for later.

In my last post you can see part of a treasure chest. It weighs 82 lbs empty and has a pirate pistol (fake) hidden in the lid for your last chance to shoot the dirty rotten scoundrel that is forcing you to open your treasure ! !

Wood working.......Here is some photos of a set (read double single beds here) of futon platforms I made and sold. The client needed to have some way to store these platforms when they were not in use. They were only removed and assembled when guests were spending the night. There are no screws, nails, clips, clamps ETC used in any of the assembly or the storage rack. Only joinery and wooden wedges are used and the wedges are used both for the futon platforms and the storage rack. Dual usage. Simplicity was the mode here. The first photo is in the clients home at the end of a hallway near the entrance to where they will be used. (I liked what the hanging banner says) The other photos are just to show how it all goes together. By the way...the ironwood hammer or mallet on the top shelf in the rack actually holds the rack and it's pieces all together when in storage. It is used to knock the wedges in and out. The futon platforms are Hawaiian Koa wood and the storage rack is Poplar....Enjoy

Bruce

Attachments

Sorry.....I just noticed that the mallet isn't in the hole in the top shelf. Probably in my back pocket at the time.........Bruce

Very nice Bruce. There is wood shop in Berkeley, that is a real treat to watch the crafts folks build furniture in the same style. The costs of the funiture are way out of my league.

BTW, my nephew is on Kwajalien working on a government project. He calls it "The Rock". I think he said the highest elevation is 23 feet.

Keep sharing your projects!!!

Art

Always enjoyed wood shop in HS. I do wish I had pursed wood work...

Hi Art.....Yeah Kwajalien is pretty desolate. Classified stuff goes on there. If your a diver there's some interesting things to see under water from WW2. I had a friend who worked there a while back. I only landed there on my way to Bikini Atoll to dive some of the wrecks sunk back in 1946 when they were testing Nuclear bombs on them. There's about 200 wrecks on the bottom. I dived on the Saratoga, Arkansas,Yamato, and the submarine Apegon, the sister to the one on display in Pearl Harbor War Museum. Most dives were deep. It was astounding what a sub-surface nuclear blast will do to an aircraft carrier and battleship !! I was very lucky to dive on those wrecks. You can't go there any more.

Back to wood working. Currently I'm building a wooden mock-up of a rollbar for my Speedster and am ready to take it and the car to someone who can fabricate it for me. The guy I planned to use to do this is not reacheable so I'm looking for someone else to do this down here around Pasadena or LA area. If anyone reading this knows a source, let me know..........Bruce

What I've noticed, Bruce, is that when the roll bar has the same curvature as the top of the windshield it looks much better (and suits the car way more), so keep that in mind.

Your nearest VW shop should be able to direct you to any number of fabricators in the area that can build a roll bar.

Your nearest VW shop should be able to direct you to any number of fabricators in the area that can build a roll bar.