It's been nearly 100 degrees in Mississippi all summer. We're looking forward to Fall and some cooler temperatures, but the high today will be 96 with high humidity. It's HOT.

I think I may have a cooling issue with my car. I have a 2110 engine with a 911 shroud ( I know Raby's shroud is better but this is what I have). Normally the the temp will be about mid gauge. It has never overheated (into the red), according to the Porsche 914 temp gauge, but the needle will go to the far right of the gauge. Has never been in the white, but near there. I use the Speedster for kids football and home coming parades. That's where the issue first reared it's ugly head.

I took it out a couple of weeks ago and thrashed it for half an hour and the temp rose to about 3/4 of the gauge. I'd really like the temp to stay about middle of the gauge.

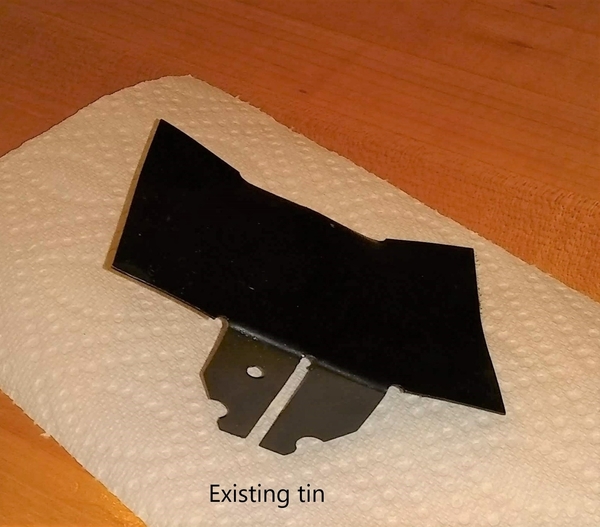

So, not being satisfied with the amount of oil on my garage floor I pulled the rockers and push rod tubes, again, and had a look at the cylinder tin.

This is what's there now.

This is what I have bought.

Is anyone using this tin on a type one engine?

Does it help the cooling?

Is my engine running too hot for the temperatures we're experiencing?

Am I fixing something that doesn't need fixing?