Ok, so last night I started this journey by actually ordering some things. If you're not into details, skip this post and come back once I start putting pictures up.

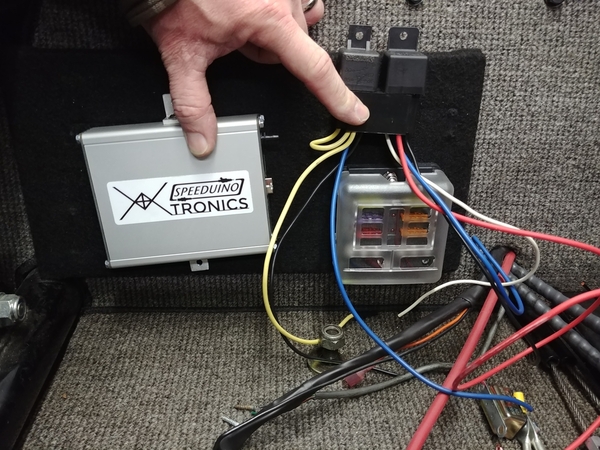

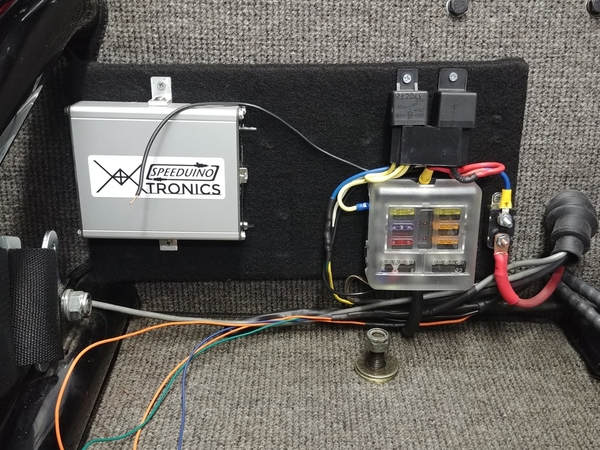

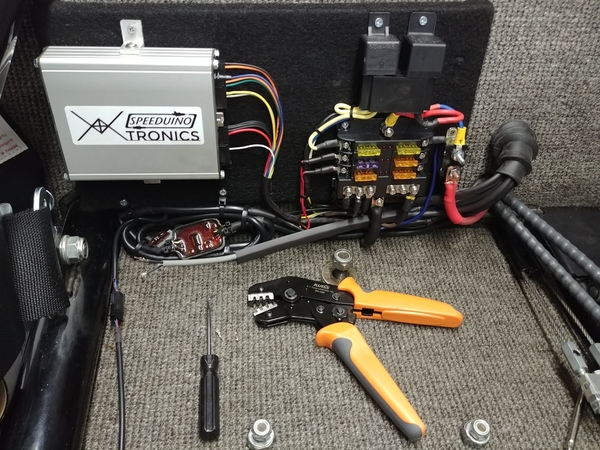

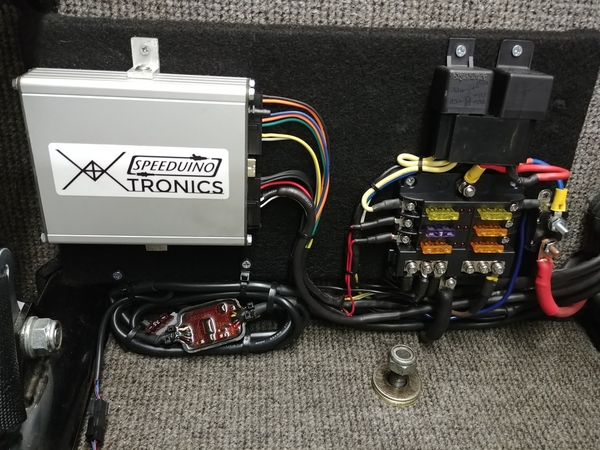

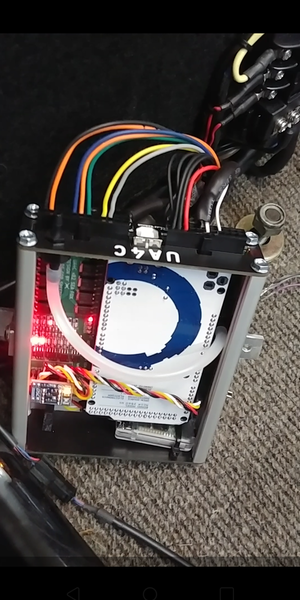

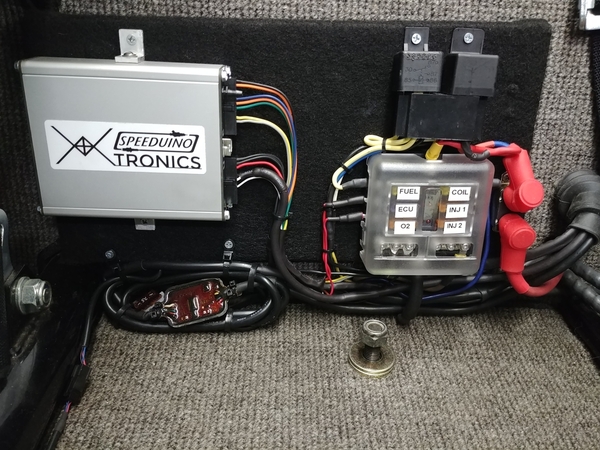

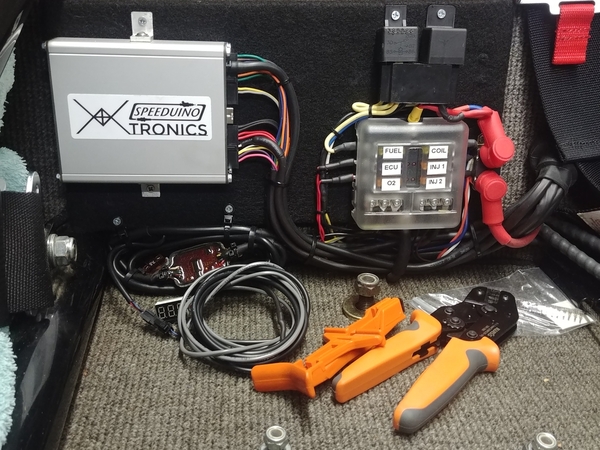

I have an ECU on the way. Speeduino UA4C from WTMtronics in Michigan.

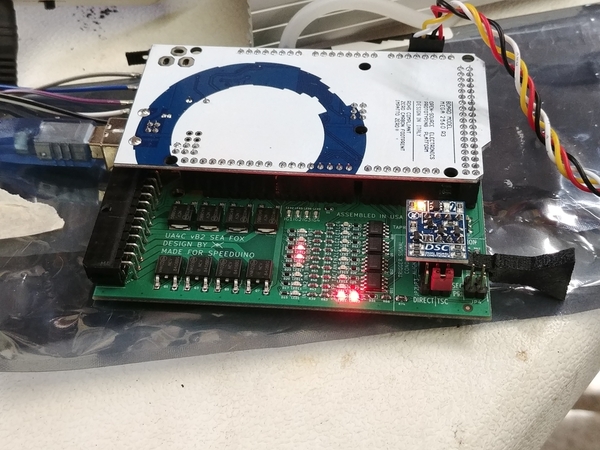

It's a Speeduino board designed by Weaver Markel and Josh Stewart. Josh is the mastemind behind the whole Speeduino thing and Weaver started making boards and distributes in the USA, as Josh is in New Zealand(or is it Australia?). They teamed up to design this one. As it is an open-source project, all schematics, code, and circuit board designs are available to anyone, anywhere, for free. Or you can donate if you choose.

The Speeduino boards are mostly designed to replace a factory ECU and re-use the case, to make it seem as if nothing has been changed underhood. This doesn't lend itself to ease-of-use by people like me that are starting from scratch. There are several versions of PNP(plug and play) boards already in a case for Miatas to illustrate my point.

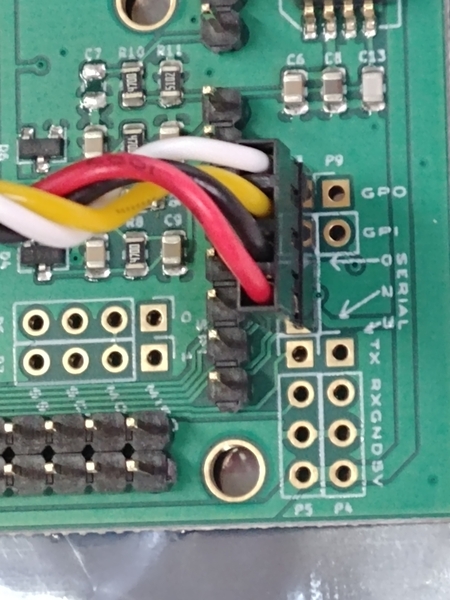

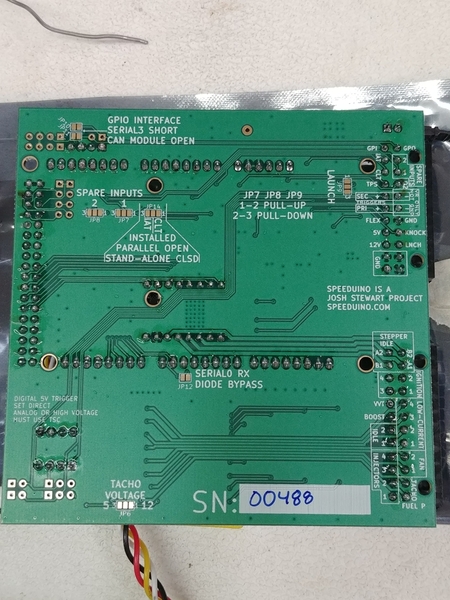

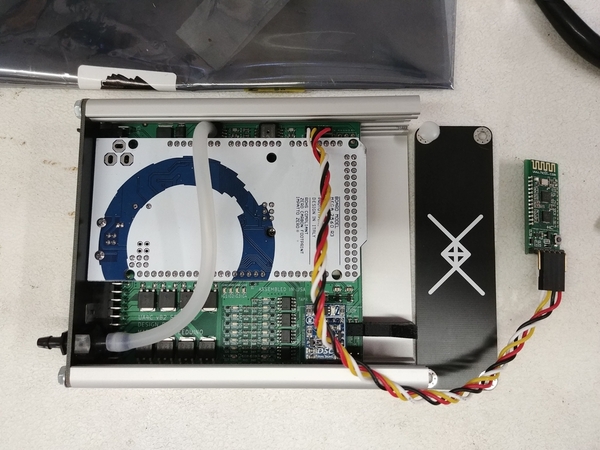

So, the UA4C. It's a standalone with a 22 pin and a 24 pin header on the end for a total of 46 input/output pins. It comes with board-mounted connectors and loose connectors and pins for making up your own harness.

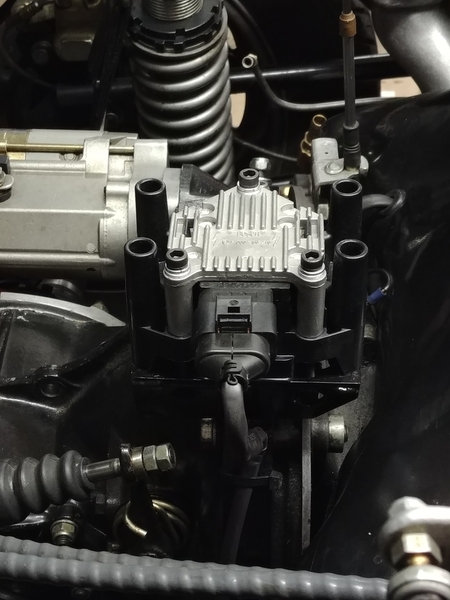

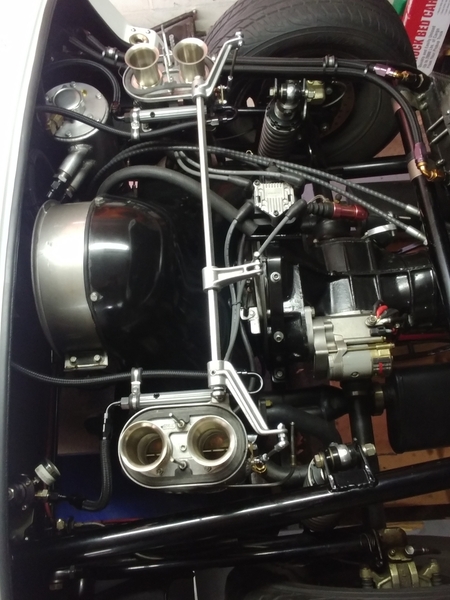

It has 4 ignition outputs and 4 injector outputs so full-sequential is possible in the future. Right now I'll do batch-fire(actually semi-sequential) injectors, 2 at a time. And I'll do wasted spark with that same VW Golf coilpack that Mike used, 2 cylinders fire at a time, one after compression stroke like normal and the other in-between. This is how MANY OE manufacturers did spark since the late 80s until recently. Now they do coil-on-plug which isn't really possible on a VW.

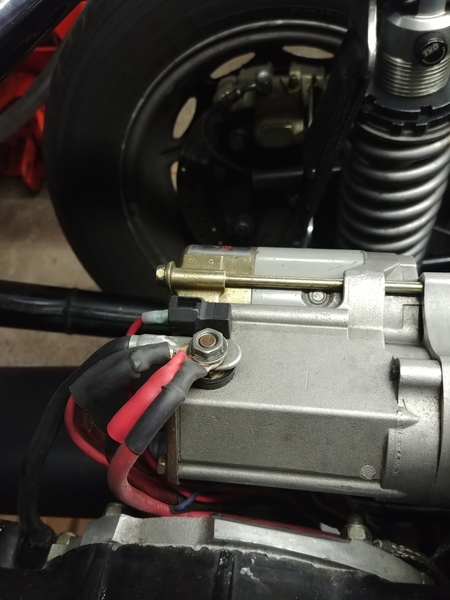

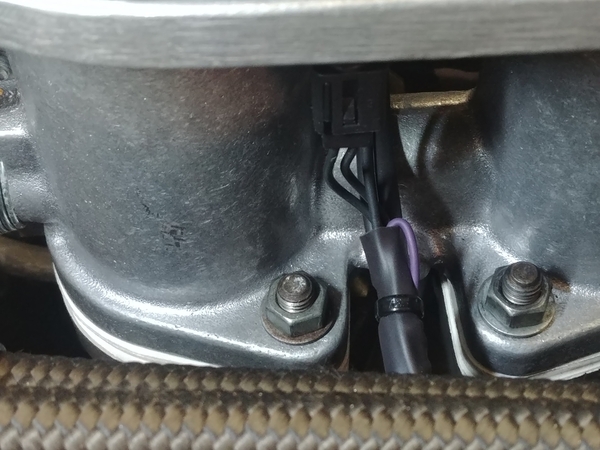

This the same way I've been running since 2008 with my Megajolt. Crank-fire(VR sensor) and wasted spark Ford coilpack. I built that from a kit of parts, and hand-assembled and soldered the through-hole components. This system has been 100% bulletproof so far.

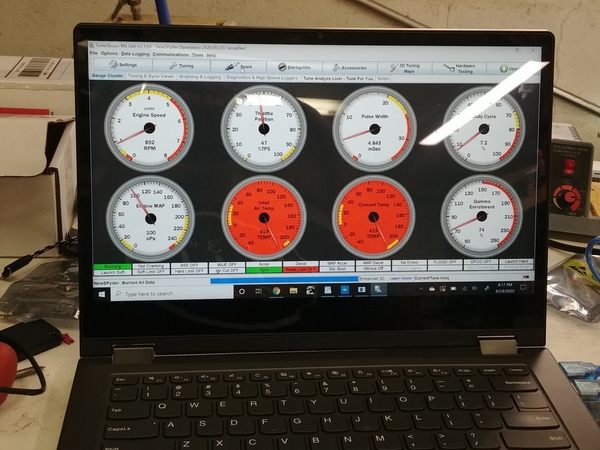

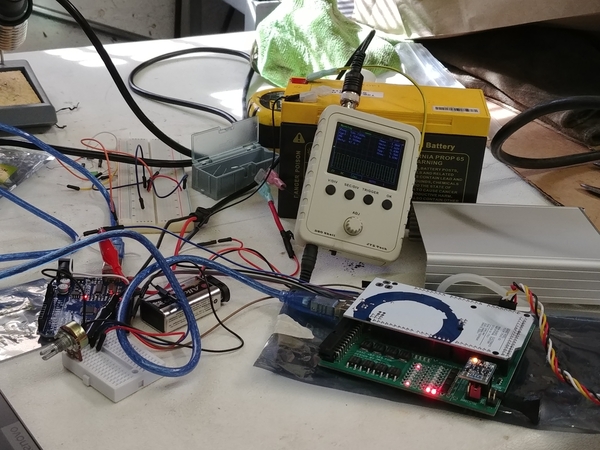

The Speeduino board uses SMT(surface mount technology) and tiny components, so the board is basically finished and pre-soldered when you receive it. I added a bluetooth board for MSDroid(cell phone app to tweak and log on the fly). I added a signal conditioner to enable the VR sensor on my crank to be used as-is. I also added a stepper idle-air valve controller for possible future use(not planning to use at this time, but for $3.50 well-worth it).

The UA4C board includes both an on-board MAP sensor(Manifold Air Pressure or in my case: vacuum) and a barometric sensor for on-the-fly altitude mixture compensation.

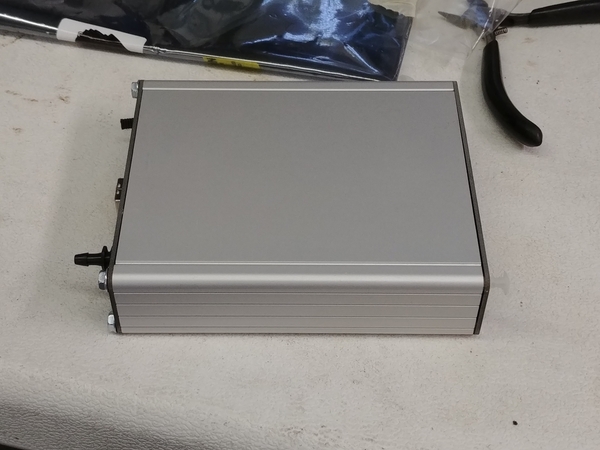

I also got the Arduino Mega that attaches to this board and is the brain of the operation here. And a nice aluminum case and custom pre-cut end plates for the case.

$187 including shipping so far.

I also ordered a new 3 pin connector from Mario at thedubshop for my existing VR sensor. $13 shipped.

Next up, I'll get some wire in multiple colors to build the harness. I already have extra shielded wire for the VR sensor.

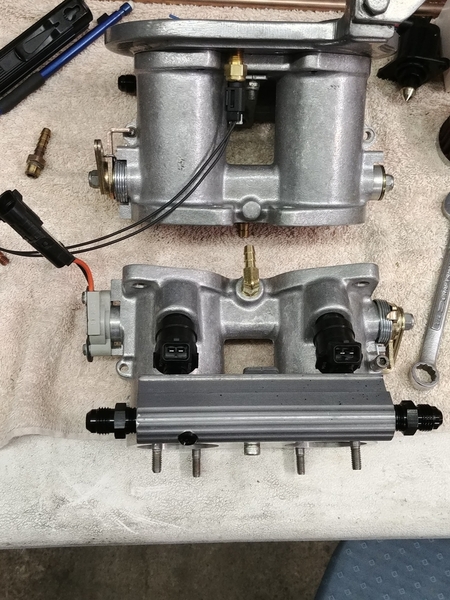

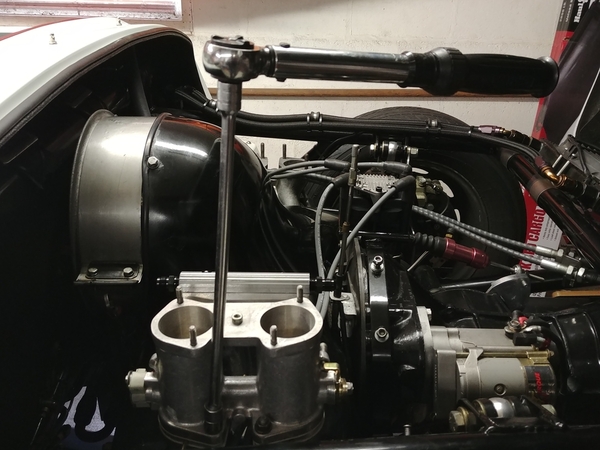

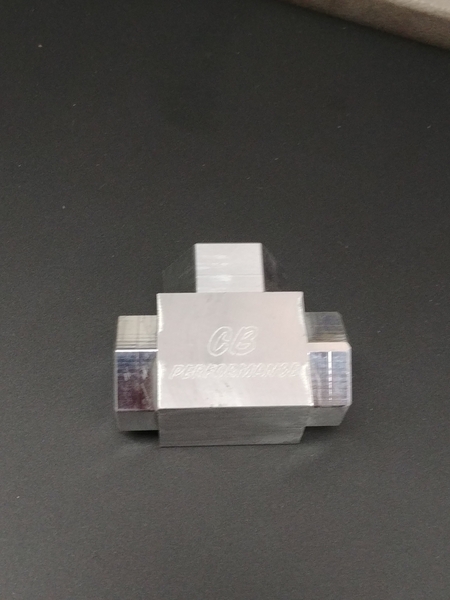

I'm about to order some new injectors and an intake air and temperature sensors from CB Performance. That way they'll surely fit my CB throttle bodies and fuel rails.

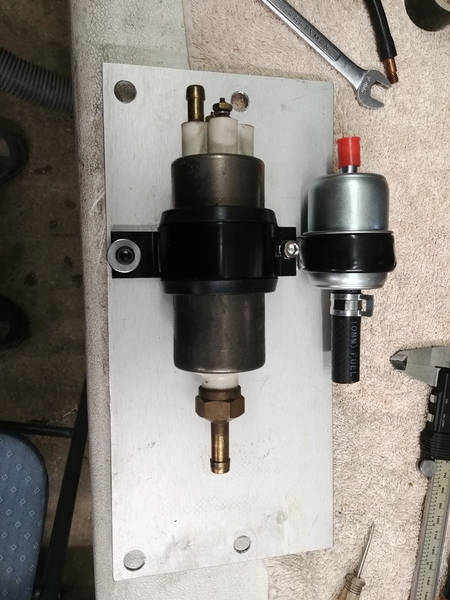

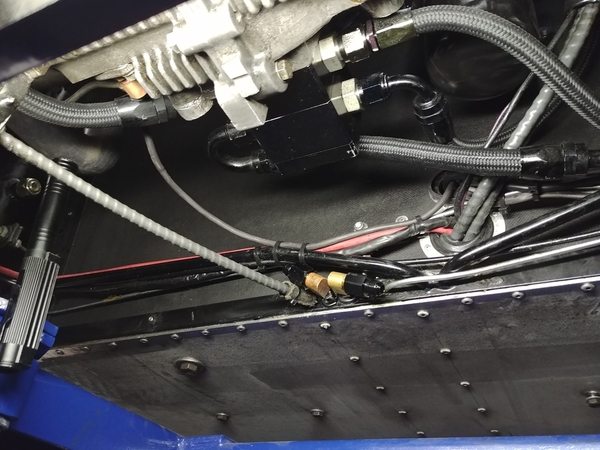

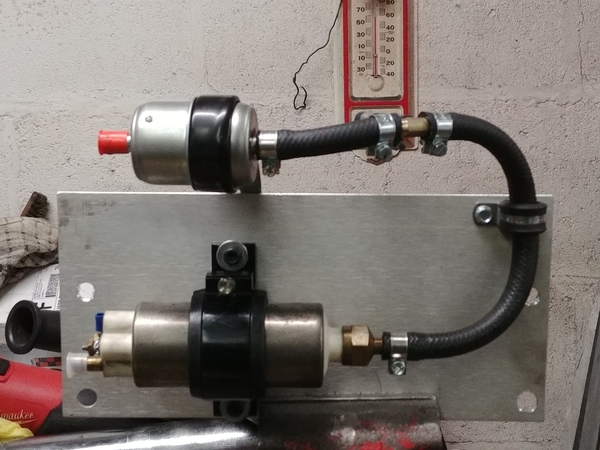

Then it will be on to the fuel/regulator/pump stuff and installing a return line through the car.

Stay tuned(LOL!)

![20200828_134343[1] 20200828_134343[1]](https://www.speedsterowners.com/fileSendAction/fcType/0/fcOid/641679540321085008/filePointer/642805549585573271/fodoid/642805549585573266/imageType/MEDIUM/inlineImage/true/20200828_134343%255B1%255D.jpg)

![20200828_193658[1] 20200828_193658[1]](https://www.speedsterowners.com/fileSendAction/fcType/0/fcOid/641679540321085008/filePointer/642805549585573272/fodoid/642805549585573267/imageType/MEDIUM/inlineImage/true/20200828_193658%255B1%255D.jpg)

![20200828_134343[1] 20200828_134343[1]](https://www.speedsterowners.com/fileSendAction/fcType/0/fcOid/641679540321085008/filePointer/642805549585573271/fodoid/642805549585573266/imageType/SQUARE_THUMBNAIL/inlineImage/true/20200828_134343%5B1%5D.jpg)

![20200828_193658[1] 20200828_193658[1]](https://www.speedsterowners.com/fileSendAction/fcType/0/fcOid/641679540321085008/filePointer/642805549585573272/fodoid/642805549585573267/imageType/SQUARE_THUMBNAIL/inlineImage/true/20200828_193658%5B1%5D.jpg)

![20200913_185425[1] 20200913_185425[1]](https://www.speedsterowners.com/fileSendAction/fcType/0/fcOid/641679540321085008/filePointer/644776185533929106/fodoid/644776185533929099/imageType/MEDIUM/inlineImage/true/20200913_185425%255B1%255D.jpg)

![20200913_185446[1] 20200913_185446[1]](https://www.speedsterowners.com/fileSendAction/fcType/0/fcOid/641679540321085008/filePointer/644776185533929107/fodoid/644776185533929100/imageType/MEDIUM/inlineImage/true/20200913_185446%255B1%255D.jpg)

![20200913_185514[1] 20200913_185514[1]](https://www.speedsterowners.com/fileSendAction/fcType/0/fcOid/641679540321085008/filePointer/644776185533929108/fodoid/644776185533929101/imageType/MEDIUM/inlineImage/true/20200913_185514%255B1%255D.jpg)

![20200913_185843[1] 20200913_185843[1]](https://www.speedsterowners.com/fileSendAction/fcType/0/fcOid/641679540321085008/filePointer/644776185533929109/fodoid/644776185533929102/imageType/MEDIUM/inlineImage/true/20200913_185843%255B1%255D.jpg)

![20200913_185425[1] 20200913_185425[1]](https://www.speedsterowners.com/fileSendAction/fcType/0/fcOid/641679540321085008/filePointer/644776185533929106/fodoid/644776185533929099/imageType/SQUARE_THUMBNAIL/inlineImage/true/20200913_185425%5B1%5D.jpg)

![20200913_185446[1] 20200913_185446[1]](https://www.speedsterowners.com/fileSendAction/fcType/0/fcOid/641679540321085008/filePointer/644776185533929107/fodoid/644776185533929100/imageType/SQUARE_THUMBNAIL/inlineImage/true/20200913_185446%5B1%5D.jpg)

![20200913_185514[1] 20200913_185514[1]](https://www.speedsterowners.com/fileSendAction/fcType/0/fcOid/641679540321085008/filePointer/644776185533929108/fodoid/644776185533929101/imageType/SQUARE_THUMBNAIL/inlineImage/true/20200913_185514%5B1%5D.jpg)

![20200913_185843[1] 20200913_185843[1]](https://www.speedsterowners.com/fileSendAction/fcType/0/fcOid/641679540321085008/filePointer/644776185533929109/fodoid/644776185533929102/imageType/SQUARE_THUMBNAIL/inlineImage/true/20200913_185843%5B1%5D.jpg)