This is the same Stainless steel that you see in some of the Burger King's on their table tops and paneling. It is 1.5" engine turned circles on 22. ga metal.

Make a "CAD" with poster board first, then trace that on galvanized sheet metal from Home Depot HVAC section, do another trial fit and trim even better and to make sure you can get the whole piece of sheet metal in. (the cardboard is easy to bend and fit in but sheet metal isn't). Finally, cut and fit the stainless.

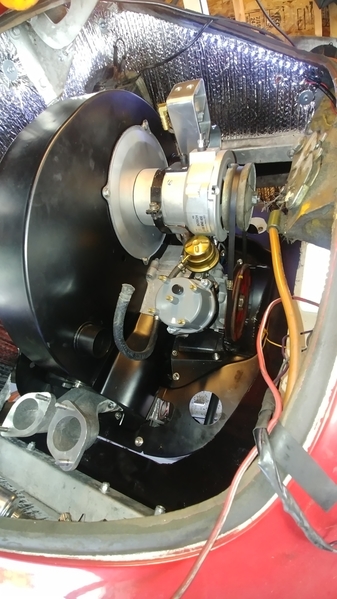

This could be done with sheet aluminum, brass, copper etc. Heck, we have even seen diamond tuck leather upholstery used ! I think shiner is better ! Also an LED flexible lighting tube fastened up under the lip all around the engine lid hole where you can't see it really highlights the entire engine compartment.

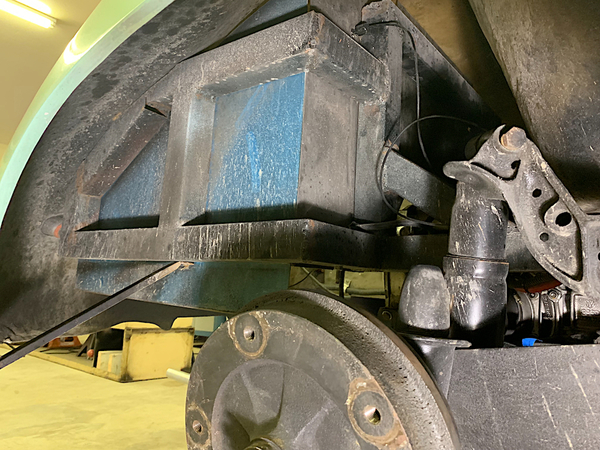

My next project is a Spyder. It will have the same firewall veneer of stainless. I had to get the fire wall panel first and fit it with the stainless before it goes in the body with the frame though. I just like the way it looks and it doesn't scuff up like aluminum does over time from cleaning and wiping. Do what ever you wish but do it right or it won't ever look right to you............Bruce