Today's update: built out the fuel pump system from the gas tank to the engine bay; built both of the throttle body/manifold assemblies; tweaked the throttle bodies to work with the CB Performance manifolds; ported and gasket matched the manifolds to give clearance for the injector spray.

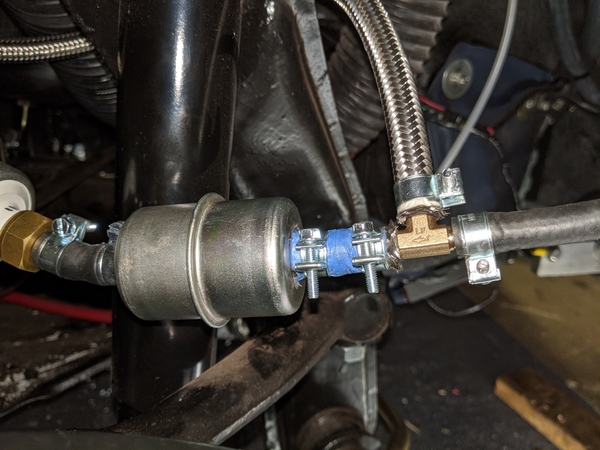

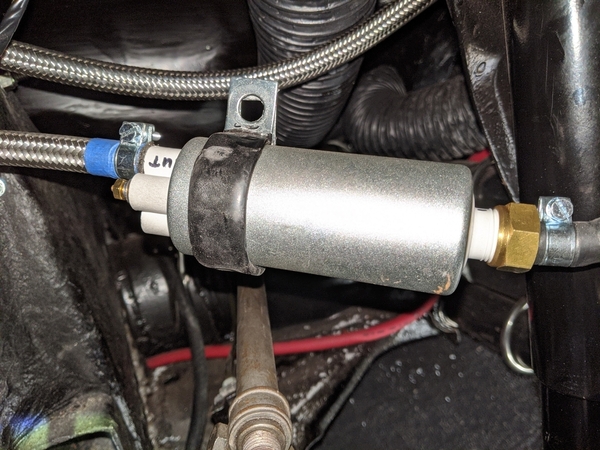

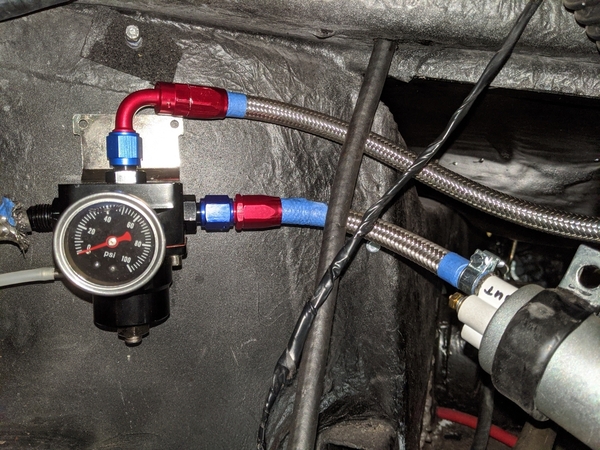

Here's the gas tank side. The tank feeds a brass T connected to the first gas filter and the fuel return fitting on the regulator. The first filter connects to a Powerco high pressure inline fuel pump (around $50 from Amazon). The pump feeds the pressure regulator which feeds the second gas filter. The second filter connects to an AN6 steel covered fuel line that runs to a firewall AN6 bulkhead T that provides 2 AN6 fittings in the engine bay.

Tank side

Short run to brass T then filter and pump

Brass T with fuel return from regulator

High pressure pump

Regulator

2nd filter and feed to the engine bay and vacuum line from manifolds to the pressure regulator

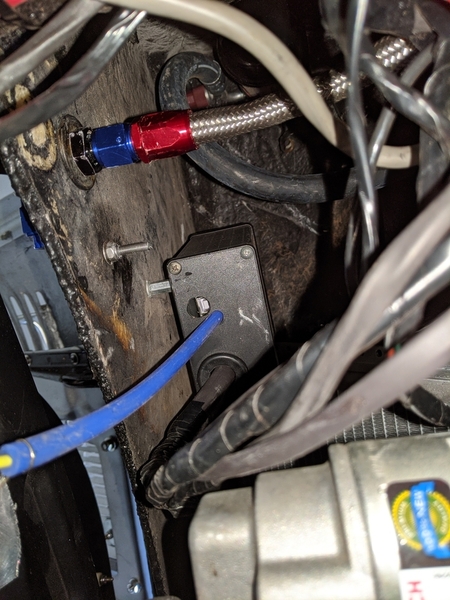

Gap between firewall and backseat. 6AN bulkhead fuel fitting and Speeduino mounted on back of the firewall. Blue hose is manifold vacuum

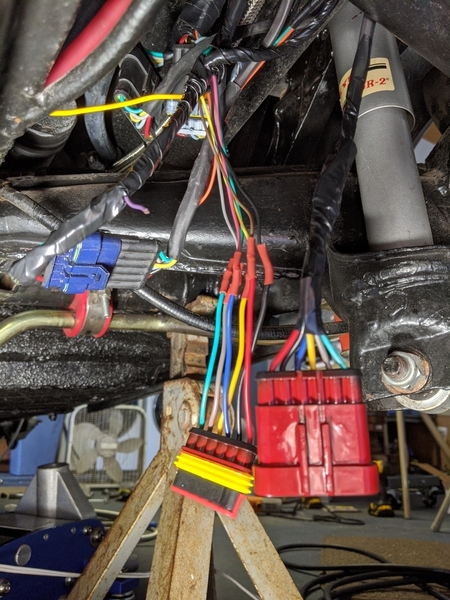

Speeduino connections broken out into 6 pin waterproof connectors

Splash guard installed underneath Speeduino

GM intake air temperature sensor tied to the stake inside passenger side air filter. Wires run through 3/16" hole filled with black RTV.

Gasket matched to throttle body

Gasket used as template for porting manifold for injector

Tomorrow I'll build out the fuel hoses in the engine bay and finish wiring up the injectors, throttle position sensor and intake air temperature sensor.