Is this what your looking for ![]()

Same no difference

IaM-Ray posted:

Is this what your looking for

Yep. You have the same thick rubber bumper. The handle I bought doesn't match up with the original holes in the dash and rubber.

Alan Merklin posted:Same no difference

You mean it's the same handle? The holes matched up without the rubber bumper but is way off with the bumper attached.

Weird. I positioned the dash rubber using the original holes in the rubber and the dash. The original grab bar must have gotten lost in in the 14 years that it sat so I don't have a comparison.

If Alan says they're the same, it's good enough for me. I can redrill the hole under the dash and stretch the leather downward and make it look decent if I put a big gasket up top.

Ok, working on the top installation. I was inspired by the fact that it sprinkled rain at our house yesterday. The winds had shifted and were coming from the south. That meant that the 10,000 foot Haleakala wasn't shielding us from the normal rains you get out in the Pacific. We call the south winds "Kona winds" since the west coast of the big island is to our south. In any event, Maui gets lots of rain everywhere but where we live, so a top is a good idea.

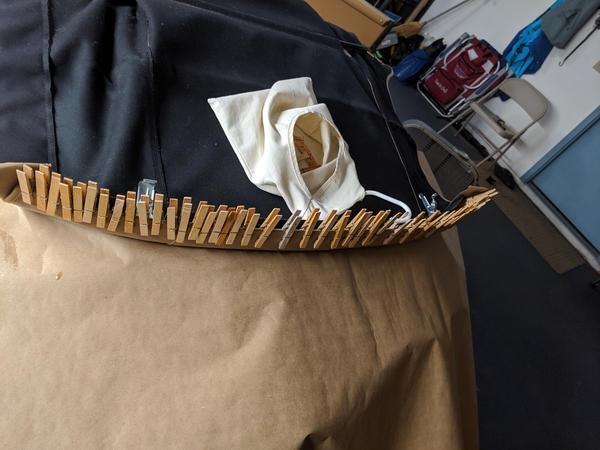

Everything is proceeding well. Great instructions from Gordon, Alan and others. The header bow has been glued and now the edge of the fabric has been flipped over inside the bow and glued. It is in the process of drying.

Fortunately, I had previously sourced some bespoke, custom German wooden clips that were in limited use during the construction of the original Porsche 356s. They are designed to hold the fabric against the glue inside the header bow as it dries. This ensures a crisp, taut edge of fabric against the bow and prevents wrinkles that might besmirch my concours aspirations. Looks like it's working out as planned...

Screechy engine noises not related to slipping fan belts. I heard a short, disturbing screechy noise and there started to be oil drips from the pulley area. I pulled the crank pulley and fished out the washer behind it... Wait a minute, there is no washer behind the pulley, only the oil slinger. Somehow, the oil slinger got torn into two parts, a washer size part and a larger ring that is loose, but too large to come out of the crank nose hole. Don't I have the most unusual challenges...

I haven't figured out what caused the slinger to tear apart. Anyone else ever seen this? The engine sat new, but unrun, for twelve years before I bought it. I've put 175 miles on the engine in the last month or so. No obvious large debris in the crankshaft nose area.

In any event, I'm pulling the engine and will split the case in the next day or so to see what's going on and what it will take to put things right. The best scenario is a cleanout and just replacing the slinger and maybe the rear main bearing. When I drained the oil, no big chunks of anything were evident. The magnetic plug had normal break-in dust size particals on it, but nothing that suggested violent disaggregation. Please, please, please...

Oh, and for those of you who wonder if woodruff keys ever act like little bastards, here's a picture of how I finally persuaded the crank key to leave the loving embrace of its favorite crankshaft (after vicegrips, pb blaster, torch and gentle conversation extolling the exciting world outside of the crankshaft nose). Sometimes it just takes a slide hammer.

Well, I gotta hand it to you.

You really get some weird ones.

Gordon Nichols posted:Well, I gotta hand it to you.

You really get some weird ones.

Someone must have wished an interesting life upon me. If I'm honest, I don't really mind solving problems, I just wish there was a bit more time to get bored in between.

Should be interesting to see what you find in there. The pieces are consistent with the outer rim of the slinger contacting the case within the slinger void (and also jamming the woodruff key in the crank slot), but I can't imagine why, other than there were two different washers used by VW: 51 - 60 and 61 - 79. I don't know the differences in diameter, but these guys should be able to tell you (and maybe the wrong one was used when the engine was built):

Bug City

| Phone, Fax & E-mail |

| Toll Free: 1-888-BUGCITY (1-888-284-2489) Within CT: 860-666-CITY (1-860-666-2489) Fax: 860-665-1396 Contact US |

email info:

Thanks, Gordon. Lowering the engine right now. Then a 3 hour break to tour the local bird sanctuary (Marianne decided to make me take a break :-)

Deja Vu all over again.

I originally bought a built-up 2,110 long block and finished the peripheral stuff myself. When I first started it up (after it had been sitting in my shop for two years) it ran with an ok, un-sync'ed idle, for about 15 minutes just outside of the garage and then I shut it down. 15 minutes later I wanted to move it back into the garage so I started it up, it ran for about 15 seconds and seized. I ended up pulling it down to the crank.

Turned out that whomever had built the long block skewed the #4 main bearing (next to the flywheel) during case assembly and caught the towel pins slightly off in the bearing, squeezing it tight. Used a propane torch to heat the seized bearing and it slid right off. ![]() New bearing set got installed and started over again....

New bearing set got installed and started over again....

Enjoy the birds. It'll be god to get your mind off of this for a while.

Mike, the good news is that most probably it won't cost much but your time to take it apart and reassemble. It's just time and some gaskets and maybe a bearing set and some sealant. Maybe new pushrod tubes and seals depending on the style that you have.

Chin up, move forward, and you'll be fine.

Engine rebuild update. Good thing I have two feet cause I keep shooting myself in one of them.

After I split the case, I saw I was wrong about about the oil slinger breaking. It turns out that there WAS a washer behind the crank pulley for some reason. The pulley wasn't a sand seal as far as I could tell (had reverse threads). The slinger was intact and didn't show any wear.

The shot to the foot was a ground up brass timing gear from failing to remove the distributor drive when I plugged the distributor hole. I now am very aware of what happens. Fortunately the steel crankshaft seems to have ignored brass. The front bearing surfaces showed some light scoring so I probably caught it early.

In any event, a full set of bearings, sealant, gaskets, studs and seals are arriving this week. I also ordered. 12" long 7/32" drill to do the Hoover mods for the case.

Onward!

Always be on the lookout for those brass thingies...

Since I'm rebuilding the engine, what should I consider tweaking while I've got the case split? I'm just looking for a basic reliable power plant, but won't turn down a few extra ponies or ft/lbs if it makes sense.

Here are the basic specs culled from the ad when I bought it:

1776 cc built on a duel oil relief AJ series case

Engle 110 cam and gear

lightened and balanced connecting rods

69 mm crankshaft

90.5 mm piston and liner set

~ 8:1 compression & 52.5cc chambers

hardened lifters

042 heads

40 mm duel Kadrons

full flow oil pump (30 mm )

chrome moly head studs

case savers

Here are engine pics that might trigger some ideas. I know @ALB will have some thoughts on this.

Many thanks,

Mike

Easiest, cheapest thing I can think of is ratio rocker arms. Those in the photos look like 1:1

But then, you’ll need different push rods, too.

And maybe sealed, adjustable pushrod tubes.

How soon do you want to be back on the road?

Best to clean it up and put it back together nicely. You've got 85 horse in a reasonable power band with this set up. It should give peak torque at about 3500 and pull strong to 5000 or a bit more. The Kads are matched to the cam, compression, heads, etc.

What's your disty? A standard Chinese 009, right? With a Pertronix?

If so, fix that first and regardless. All the cool kids are doing it, and it reportedly makes THE difference in the parts of your power band where you will actually be operating this engine.

You buy a set of 1.25 rockers, your valve lift goes from .430 inches to .490, and effective duration is now over 300 degrees. Assuming that works with your valve springs and fits in your combustion chambers, that's great for a hotrod—but without a couple Weber 40s, some head work (ah screw it, just buy a set of Panchitos) and possibly a more deliberate exhaust system you won't get all of what you should be getting.

With the 'Chits and everything else dialed in competently you'll gain [help me out here, experts] what? Maybe 15-20 hp? If everything is assembled right you'll now peak a little above 6000 rpm and your best torque will now be around 4200. You'll lose a little grunt below 3000.

Without the heads and carbs ($1500 and shipping?) the rockers might net you 5hp at 5200 but they will still move your torque band up and away from where normal humans typically operate internal combustion engines on public roads AND require a bunch of fettling to make it run as well as it would have in the lower mid range without the changes.

edsnova posted:(ah screw it, just buy a set of Panchitos)

^ That. Then put the 1.25s on it, buy a "Black Box" (to you know, "save on shipping") and call it a day. There is zero downside to Panchitos on a 1776.

Next year when you want more, you can start writing checks again for a merged header and some better carbs. The heads won't be the limiter at that point.

Gordon & Ed, I just measured the rockers and they are 1.25 ratio (35 mm and 28 mm centers perpendicular to center of shaft). I'm going to stay with them since the difference with this lower performance setup is probably a torque/hp wash in terms of the buttometer. The ignition system is a Speeduino ECU driving a 2000 Golf 2.0L ignition module in a wasted spark setup. The ignition curve is basically what I derived for my old 3.3L turbo engine proportionally mapped to the idle and top end advance that seemed to work for the 1776. I currently run 10* at idle and top out at 40* without any detonation. It's running rich so I may need to drop advance a little if I change jets, but that's not high on the priority list right now. If any tuning junkies have a suggestion on the spark map let me know.

Thanks!

Screw it. Just put it together as-is and drive the guava out of it.

Everything you do from what you have now gets expensive really fast.

Gordon Nichols posted:Screw it. Just put it together as-is and drive the guava out of it.

Everything you do from what you have now gets expensive really fast.

Panchitos are $610 for a set of 2. I'm going out on a limb here and suggesting that in this day of $6500 5-speeds, $610 does not qualify as expensive.

Again: zero downside.

I suspect I'd have to catch Marianne really full of "Christmas spirits" to get a sign-off right now on $800 worth of Panchitos (cause you know I'd need just a little bit more compression plus shipping costs if I went that way). Maybe after that nice cruise we've got planned next year to Norway, Sweden, Russia, Germany and Estonia...

Gordon, sounds like a good plan. I'll just clean it up and drive the guava out of it for a while, unless my oil slinger gets temperamental again :-)

Mike, under WOT, you should be around 28-32 degrees advance up to about 4800, then retard the advance(under WOT only) 4 degrees per 1000 rpm above 4800. I would also go from 10 up to 30 gradually on WOT from 1000 rpm up to 4800.

The retard advance over 4800 was a gift from Jake Raby to me. It works superbly, you don't need high advance way up there.....

Under light load, I'm up to about 36 degrees with light load at 3000 and up.

Otherwise your curve is nice. I have tweaked mine continuously for ten years and am on version 40......

Personally, I'd up compression to 9:1, at LEAST 8.5:1. Panchitos would be great on this motor, but it's not my money. I like JayCee no-leak pushrod tubes and white silicon seals.

I want to know more about the retard @DannyP. Without a dyno, I'm just guessing (and trying to feel it: was that faster?) out here in flyover country.

Hi Mike- As you well know, any changes are going to cost money. Let's start with the easy ones-

First- as has already been mentioned, for an easy power increase throughout the rpm range, raise the compression. At 8:1 with 52.5 cc combustion chambers the engine must have up around .060" deck height. While those numbers work, a .015 or .020" drop in deck will up the compression to 8.5:1, make the engine more efficient, and may even run a little cooler. The increase in power won't be earth shattering, but will be felt from idle on up and be good for mileage as well. That engine also needs a set of solid bolt together (no spring washers or circlips) rocker shafts- it's only a matter of time before a washer or circlip breaks, and that could spell disaster! And at that valve lift (.430"?) some elephant's foot adjusters would be easier on the valve train.

I would NOT put Panchito heads on a 1776 that doesn't make power above 6,000 rpm. The small gain you'll get in the top rpm's doesn't justify the loss of airspeed (and fuel dropping out of the mix) through the intake ports the engine will experience in the lower part of the powerband. This loss will translate into an ever so slightly soggier bottom end/ low midrange (where we do 95 or 97% of our driving), which you may or may not even really feel, but the resulting (albeit probably small) mileage loss will tell you the combo isn't optimal.

The heads look like they have stock combustion chambers with shrouded valves and no port work- how do the intake manifolds line up with the intake gasket holes? If you are looking for more power (and to spend a little more money), a set of properly ported 35 (or even better 37) x 32 mm heads would be a better choice. Ported 35x32 heads will support 120 hp (and I imagine another 5- 7? hp with the slightly bigger intake valves) and will retain all the drivability stock heads deliver. At this point flycutting the heads to 50 cc combustion chambers will give 8.9:1 (.040" deck) and still run on 91 ron (premium) gas. As Gordon mentioned, those look like 1.1:1 rockers- on 1.25's usually the pushrod cups are drilled noticeably closer to the inside edge of the face, but hey, we could be wrong (ask my lovely wife- she'll tell you it's not the first time!). VW 1.1:1 rockers have 2 raised lines on the forging. With a 1½" exhaust and 1.25 rockers (which will add 4-5° to the dur @ .050") the engine should rev to 6,000 rpm with power. I'm told (by someone who's information I trust) Kadron manifolds with ¾ of the center divider ground out will idle as nicely as Webers/Dellortos.

Hope this helps. Al

@Stan Galat- retarding the timing for better power above 5,000 rpm is an old drag racer's trick.

PS- Do the Hoover mods- you'll be glad you did!

@DannyP thanks for the spark table info. I'll definitely be adopting your suggestions. @ALB spot on ideas. I appreciate all of your help very much!

I can do port matching on the manifolds and heads if you think it's worth the time. Right now the intakes manifold openings are slightly larger than the manifold outlets (theoretically reducing the backflow). Gaskets are cut to be out of the way. I've already modified the Kadron manifolds to open them up to about an inch from the bottom. Seemed to be idling fine before I dropped the engine.

I'll measure the rocker lift ratio directly tomorrow to see if I screwed up the arm length measurements. I'll raise one side an inch and see how far the other side moves.

Rookie question, when heads are designated as "042" or "044" what does that mean? I can see that it doesn't directly correlate to valve size. I'm sure it's obvious but I've not been able to figure it out.

Thanks!

Mike

mppickett posted:I just measured the rockers and they are 1.25 ratio (35 mm and 28 mm centers perpendicular to center of shaft). The ignition system is a Speeduino ECU driving a 2000 Golf 2.0L ignition module in a wasted spark setup...

Well alrighty then! I hereby retract everything in my post after the first sentence.

ALB posted:

I would NOT put Panchito heads on a 1776 that doesn't make power above 6,000 rpm. The small gain you'll get in the top rpm's doesn't justify the loss of airspeed (and fuel dropping out of the mix) through the intake ports the engine will experience in the lower part of the powerband. This loss will translate into an ever so slightly soggier bottom end/ low midrange (where we do 95 or 97% of our driving), which you may or may not even really feel, but the resulting (albeit probably small) mileage loss will tell you the combo isn't optimal.

On the contrary: the Panchos are designed to make more air speed through the intake ports. That's their whole schtick: you get high flow numbers at high RPM and, unlike a BugPack 044 or similar, high velocity at the low end so you don't lose low and midrange torque.

Not saying it makes sense to upgrade this engine at this time but the Panchos, if they perform as advertised, would not cause a soggy bottom. Quite to the contrary.

As for what you have now... I don't know, and Shoptalk forums are probably even less expert than us knuckleheads, but here's one guy's post on that subject.

This is the MFG page for what you have.

ALB posted:I would NOT put Panchito heads on a 1776 that doesn't make power above 6,000 rpm. The small gain you'll get in the top rpm's doesn't justify the loss of airspeed (and fuel dropping out of the mix) through the intake ports the engine will experience in the lower part of the powerband.

edsnova posted:On the contrary: the Panchos are designed to make more air speed through the intake ports. That's their whole schtick: you get high flow numbers at high RPM and, unlike a BugPack 044 or similar, high velocity at the low end so you don't lose low and midrange torque.

I agree completely with Ed, and have finally found a point of disagreement with Al. One gives up nothing (as compared to a stock head) with a set of Panchitos.

A VW Mexico 043 head has 57cc of intake runner volume. A CB Panchito has 54cc. There is no "loss of airspeed" with a Pancito head. Port velocity is as good or better than a stock head, and yet it will flow 167 cfm at .500 lift. A Panchito head will outflow an "as cast" 043 at every lift from .100 to .600, often by a factor of 2x, with a smaller intake runner. At the risk of sounding like a fanboy, these heads are the best thing to hit the VW market in at least 20 years (maybe ever). Pat Downs deserves a place of prominence in the VW pantheon, and should be knighted or something.

There is zero downside to Panchitos. Zero.

Also, regarding the heads Mike's got: regardless of what the ad says they are, I'm almost 100% sure they aren't Mofoco 042s. The Mofoco castings have always been domestic (Manitowoc, WI), and the heads in Mike's first picture were Mexican castings. I'd bet a donut they are 043s.

@Michael Pickett: perhaps the best place I can direct you to compare heads, both OE VW and everything readily available on the aftermarket would be this page on TheSamba. A guy with the handle of "AlteWagen" has done a lot of work to keep it up to date.

The thumbnail is:

Tims, DRD, Headflow Masters, and everybody else take one of these raw castings and ports to their own specs and desires. CB and Mofoco have in-house CNC porting that creates different classes of heads on these same castings for different applications.

CB also makes a giant head (Comp Eliminators), as do AutoCraft and Pauter (I believe), but these heads are strictly for high-end 1/4 mile drag motors, as the port volume is enormous. There are a couple of guys in Northern Europe carving very interesting heads from chunks of solid billet, but as you would suspect- they cost many thousands of dollars.

The power is in the heads. It always has been, and always will be. An investment in heads when the engine is torn down will pay dividends down the road when a guy wants to upgrade, because (if chosen correctly) the right heads will fit the application now and when there is more potential (bigger carbs and a better exhaust).

Stan Galat posted:I want to know more about the retard @DannyP. Without a dyno, I'm just guessing (and trying to feel it: was that faster?) out here in flyover country.

No dyno info Stan, sorry. The motor did seem more eager to rev when I did that change. Originally I had an 009, and then switched to the Megajolt crankfire. Initially I had duplicated the 009 curve, and went from there with idle advance changes, added a load curve via throttle position sensor, and the retard above 4800.

A few years later I added a temp sender tied into a global advance adjustment that bumped timing when cold, at low load low rpm only to help with idle. Love the features of the Megajolt software.

All the changes made a smoother, more eager response. That's all I've got.

Al may be sniffing too much paint, I don't know. I agree with Stan and Ed, Panchitos on any motor less than 2.0 liters is a very good thing. Above 2.0 liters I'd get something bigger, IMHO they've got too small valves. Pay very careful attention to deck height, dynamic compression, and chamber size to arrive at the correct CR for max power. Tighter deck height engines can actually run cooler than large deck height low compression motors. Don't leave any performance on the table, as a cooler engine will last longer......

No problem, @DannyP - the retard gives me a whole 'nuther direction to tinker with.

There's a Stuska dyno set up for VW air-cooled engines for sale in the Pacific NW. It's $4K, obo. I can't tell you how much I'd love to have it.

I'd share it with you if we could retire in the same vicinity.....

I am hoping to have some good news to share here in a couple weeks. Don't bother guessing boys and girls, you'll find out soon enough.

“I'd share it with you if we could retire in the same vicinity.....”

We can make that happen, guys. I really think we should discuss.

I've enjoyed retiring in Maui if that's helpful...

Stan, I'm inclined to agree that I've got 043 heads. Based on the chart you linked, it looks like the only Mexican casting was the 043. Someone took the time to machine off additional identifiers so they may have been lightly touched up. Great info!

edsnova posted:mppickett posted:I just measured the rockers and they are 1.25 ratio (35 mm and 28 mm centers perpendicular to center of shaft). The ignition system is a Speeduino ECU driving a 2000 Golf 2.0L ignition module in a wasted spark setup...

Well alrighty then! I hereby retract everything in my post after the first sentence.

Ed, based on Al's info about the 1.1:1 rockers having the two lines and additional measurements I did this morning, I withdraw my speculation that they are 1.25:1.

Looks like a lightly tuned 1776 with 043 heads. Good enough for island puttering. I've had fire belching, tire shredding beasts and don't want the worry and expense that comes with them. Too many island visitors biking around each corner or staring at the sights to go too fast.

Thanks to all of you guys for your advice. On this Thanksgiving I am truly grateful for your guidance and encouragement!

Mike

Access to this requires a premium membership.

Supporting members have donated about $4.00 a month ($49.00 US per year) paid annually.

AUTO RENEW: You membership will auto-renew after 12 months. If you prefer not to auto-renew, you can cancel your premium membership at any time and it will remain in effect until the end of the 12 months. To cancel, sign in at SpeedsterOwners.com and navigate to: (Your User Name) > Premium Membership.

PLEASE NOTE: Your credit card will receive a charge from CROWDSTACK PAY, the payment processor, not SpeedsterOwners.com.