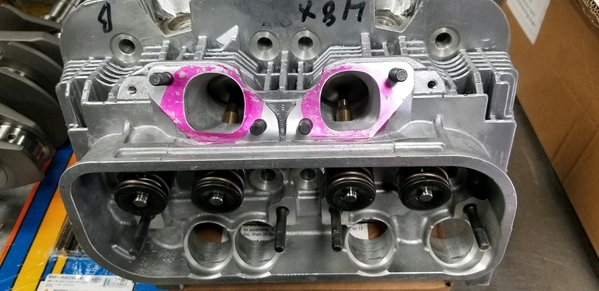

@Jimmy V. Despite detailed descriptions from me and often with photos... for those that can't take the time to read. It has become the standard way things go, this happens to me with build parts more times than you can imagine. I just ordered $6k worth of chassis parts , I'll be picking the parts up in person so I'll see how that turns out.