I’m running with my horns wired directly, no relay. So I’m good to go.

But my curiosity is nudging me to follow up on this a bit, so I may. What follows is nothing more than discussion and documentation.

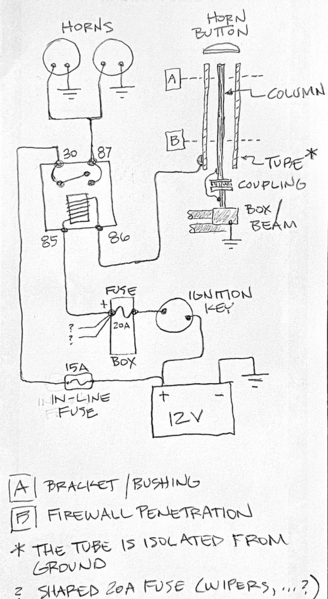

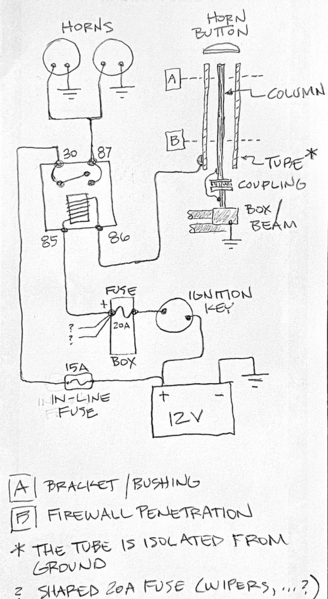

What Gordon, Mike and everyone else has said has improved my understanding of VW horn wiring. Here is sketch with a bit more detail showing what the circuit should look like using a relay to power two horns in my car. I think.

When the key is turned on, juice is just looking for a path between terminal 86 to ground. Ideally this path to ground is only provided by an intentional horn button depress, which electrically shorts the steering column tube to the column itself which is grounded. The resultant current flow through the relay coil creates sufficient magnetic field to close the relay switch, which allows current flow through the horns, hopefully loud enough to alert the driver of the large truck backing up towards me.

Clearly for this to work, the column must be electrically insulated from ground, and the tube and column need to be isolated from each other. Failure of either of these requirements can lead to unintentional horn actuation.

So back to my experience, which was: 1) turned key on, horns stayed silent, 2) pressed horn button, horns sounded off, 3) released horn button, horns remained on!

I performed a simple bench test of the relay, it worked as expected (but with less current flow than when connected to my horns).

I made some resistance measurements, but I am now treating them with suspicion until I can obtain some known resistors to verify my old ass cheap meter is working properly. If not I’ll buy a new one.

So until I can make some reliable measurements, the theory I have is that I do have some leakage to ground at the tube. If it was a dead short to ground the horn would sound as soon as the ignition key was turned, so I don’t have a dead short. The leakage does allow some current flow through the coil but the magnetic force created by this low current is not enough to close the switch. When I press the horn button, current flow through the coil rises, magnetic field increases and the switch closes. When I release the horn, current flow drops back to the low level allowed by the tube leakage to ground. The weak magnetic field created with this low current flow just happens to be enough to prevent the switch from opening.

I’m giving myself a 1 in 4 chance that my theory is correct.

I’ll share anything I learn from additional experimentation if the mood strikes me to experiment.

In the meantime, I need to start another thread about my recurring shifter woes. Always sumthin.

Cheers,

Jon