First off, I’d like to thank Theron for giving me pointers and insight before I actually owned a Speedster. I’ve been lurking in and out of this site for awhile and thought I'd introduce myself now that I actually have a Speedster.

Greeting everyone! I’ve owned my ride for about a week now and have driven a total of zero miles! ![]() I'm familiar with VW's but never owned a Bug so I'm learning, especially the underside.

I'm familiar with VW's but never owned a Bug so I'm learning, especially the underside.

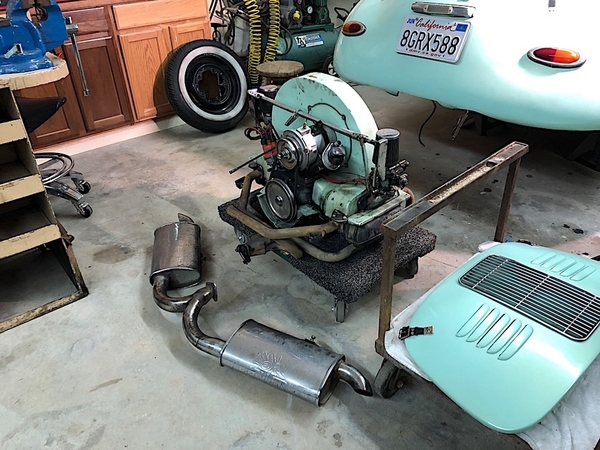

So far, from what I gather (please correct me if I'm wrong). My Speedster is based on a CMC/Fiber Fab Kit, 1969 VW Bug pan, 1600cc motor, Dual EMPI carbs, drum brakes on all 4 wheels, adjustable air shocks, electrical seems to work. It has a very bad oil leak, I'm suspecting RMS is bad. I yanked the motor out a couple nights ago.

I will more than likely go with a larger CC motor in the future but will repair the current motor and re-install to see what other repair "opportunities" may come up.

Question: Are you custom fabricating heat shroud (tins) inside the engine bay? Rubber seals used? There is no tins separating the lower part of the motor from the top, I don't see how this motor setup ran without heating up. Any photos of your setup would be great.

Any feedback or input is always greatly appreciated!