I've noticed an oil leak again on that friggn' right rear axle seal area on my older swing axle IM. I've checked the knowledge base and see that a few of you, Al Gallo most recently, have gone through a few torture sessions stopping such leaks.

I replaced the right axle tube recently and that's started a string of frustrating leaks. Apparently I didn't get the seal onto the large spacer properly while bolting all together and the seal got buggered. This morning I had time to redo everything and tore the large o ring causing another leak. I've read on this list that sometimes adding a bit of gasket sealer has been used considering the parts might not be as well finished as older OEM parts and I get that.

I checked Muir's book and he's pretty straight forward with no real tips if you get into trouble. There's an excellent tutorial on U tube by some Aussie's called Just Kampers but they show a different order of assembly which I followed. Then I checked Ron and Dave's Aircooled VW Pages and they show a completely different order of final assembly.

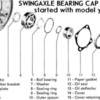

They say to assemble as much as possible into the seal holder / outer cover itself. First the oil slinger washer, then the seal, then the outer spacer into the seal, then the large o ring, then the gasket. On the axle...assuming the bearing is already installed and the backing plate is in place with the gasket behind it, install the small washer against the bearing, then the small o ring against it. This way all you'd have to do is to hold the backing plate flat against the end of the axle and use your good hand to slide the outer assembly direct onto the axle all the way home. You could have added gasket sealant if you wanted to. Get the bolts on and that's it.

I've been using EMPI gaskets, o rings and seals....all I can get locally.

I've never heard talk about this order of assembly. Has anyone done it this way....or have more advice to add ? Thanks.