Broke out the old-school spray gun for the primer and bed liner. Got it done but, in retrospect, a modern ultra-cheep HPLV gun from Harbor Freight or somewhere probably would have worked better. The #30 tip on the '60s-era Devilbiss seemed a bit miserly with the coverage....

But anyway.

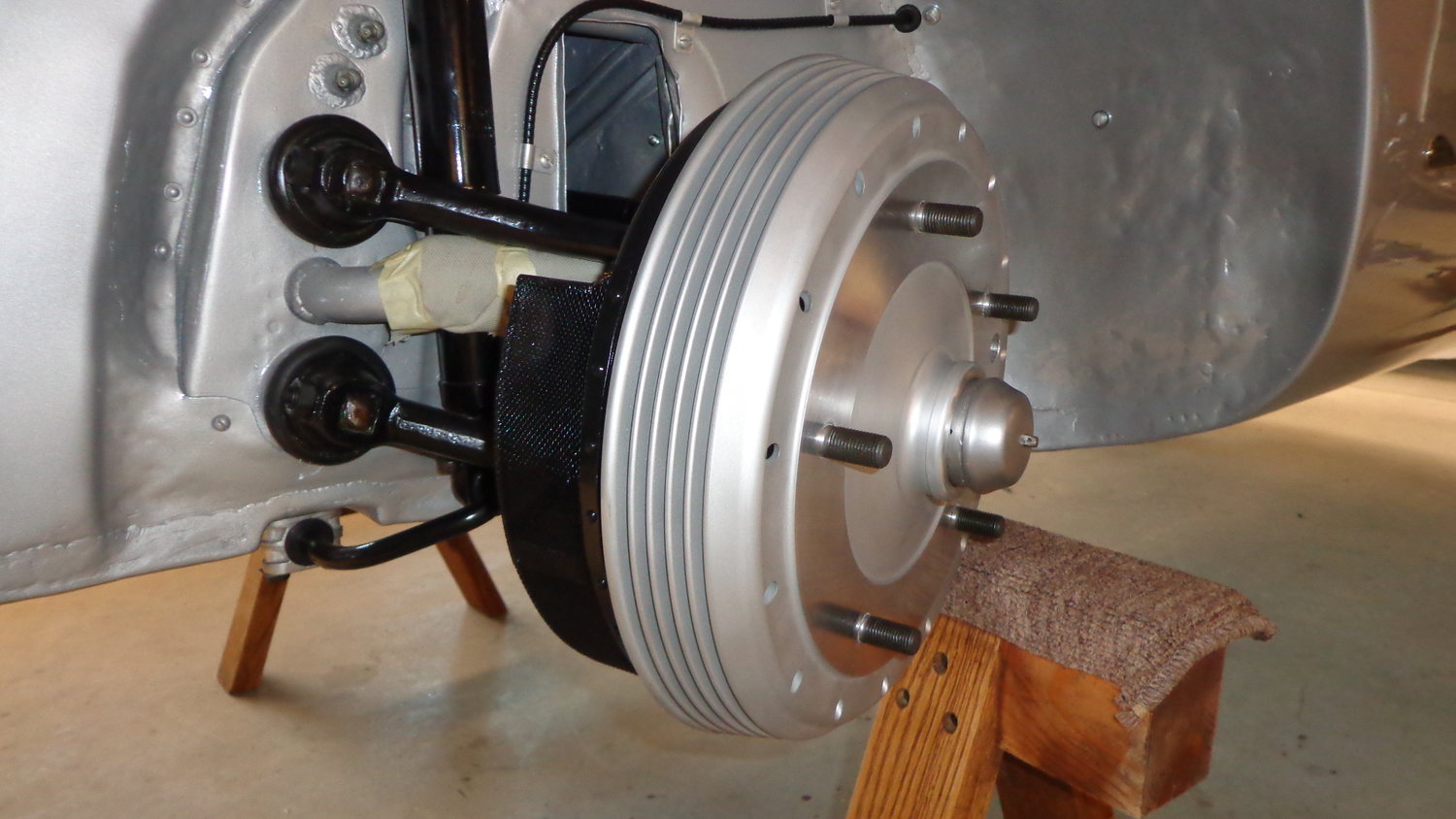

It's hard to see the silver color of the bed liner in some of these pics, and the texture is very slight—it's a bit like 120-grit sandpaper.

My rough finish is very apparent in the driver's fender well, where these wheel marks look like hammer marks. You can't even see the silver in this shot, let alone the roughness of the coating, but my tastefully-sloppy body work shines right through!

(again, for reference, Spyder Factory's meticulous high-buck all-aluminum recreation):

As this product is a 2-part urethane, I believe it can be top-coated with my body-color paint directly, but will double-check before trying that.

All-in-all a good learning day