I'll make a few quick comments here and then I'll excuse myself from this thread's notifications and if anyone needs me to look at something or reply they'll have to tag or text or PM me. I think this game of "over/under" will just irritate me... And to be clear, I am NOT upset, have fun with it, I just don't want to be irritated and I have enough on my plate as it is.

We work at the speed of right and our estimates on timeframe are just that, ESPECIALLY on custom builds. I completely understand Joel's desire to get the car quicker and everyones desire to see the build materialize quicker, but the reality is that there are a LOT of unknowns that only a builder/manufacturer could understand. There are so many cases of a client saying "let's change part A" and not realizing that a change in "part A" also effects parts "B, C, D and E", so you change those parts only to effect parts "F, G, H and I". In addition, the things we're doing with this 996 drivetrain/DME simply haven't been done in the same capacity that we're doing them, so I'm sure there are unknowns that even we haven't thought about tackling yet... BUT I have one of the best crews out there, one of the best suspension/chassis designers in the nation, one of the best electrical engineers I've ever worked with, and an assembly team from lamination to final assembly that are passionate about what they do, so I know well knock it out of the park in the end, whenever that may be.

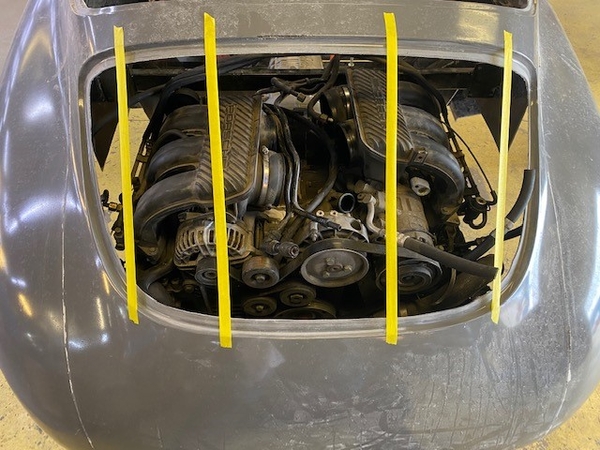

Yes, I made Joel's body out of order by several cars, his chassis was here and waiting his turn in the body mold already, same as about 20-25 other chassis. I did this so I can start mock up of the drivetrain before Joel ships it off to LN to be rebuilt. They'll be ready for it in a few weeks and I'd rather mock up with the old dirty unit and make any necessary changes based off of it. Once the mock up is completed, Joel's build will go back into its original order.

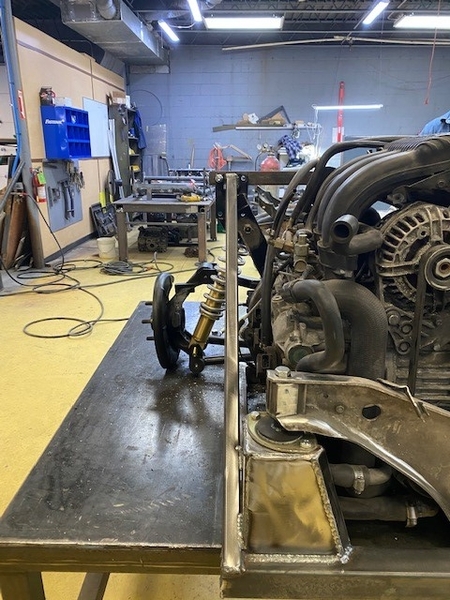

Rear suspension: using the 996 rear suspension IS possible, but will require remaking several of the cradle pieces and links in CAD and then producing modified versions of those OEM parts. Initially I ballparked $20-30K for all of the custom suspension components, which in my mind makes it cost prohibitive, especially with little to no real gain. In addition, it would limit the wheel size to something much larger and more modern, plus they would have to be custom made or recentered, so figure +$5k in wheels on top of the other custom bits. I can't justify spending that much just to say you have Porsche suspension when our stock suspension works so well, so stock it will stay (modified for the 996 biased obviously).

At this time, the stock 2" pie-widened body is our goal. I've designed slight modifications to the shock angle, and I corrected spring rate, compression and rebound for the added angle, but that change alone will allow me to get 7" of wheel on the rear.

OK, I have clients all day and the first just arrived. TTYL