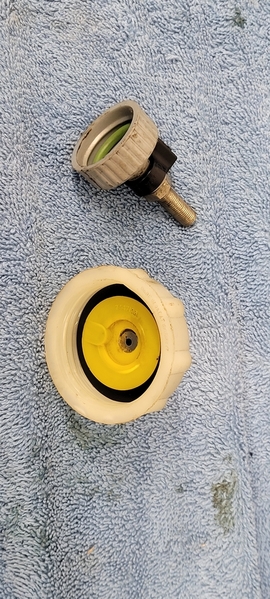

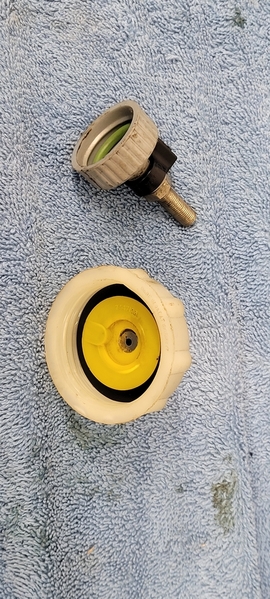

Here are the adapters I "made". I didn't really make anything, just put some stuff together. The large one is from a Wilwood/Girling MC. Make sure you drill and tap it, and go THROUGH the inner plastic or cut a hole in the rubber seal. It will also fit VW/Porsche/Audi and Tilton. The plastic seals nicely, no Teflon tape needed.

The small one is from a gear oil quart container, specifically Valvoline. It has the tapered end that you cut for whatever size hole you wish, just like a tube of caulk. The plastic is very soft, which is why the ty-rap is around it, giving the threads a good squeeze. No tap needed on this one.

The fittings are 1/8" pipe thread to Schrader valve, available here:

https://www.google.com/search?...=chrome&ie=UTF-8

We used these fittings to check and put air pressure on telephone cables(to keep them dry) at my job.

I put a green Viton O-ring in the gear oil/small VW-style adapter, keeps leaks to a minimum.

Again, no more than 10-15 psi, and check your reservoir OFTEN and refill. Make sure you release the pressure from the valve before unscrewing. Ask me how I know LOL!

This method works VERY VERY well for fluid replacement. If you're filling a new system, the tried and true 2-person pump/bleed method may be needed.