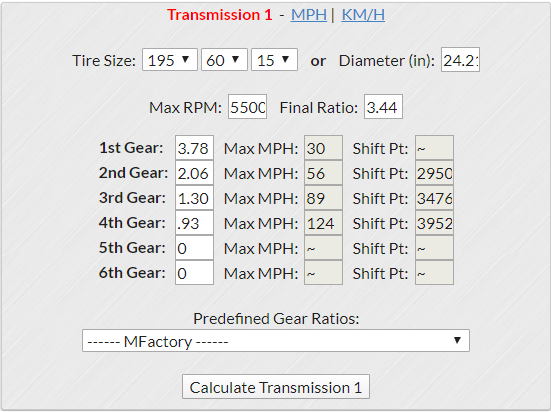

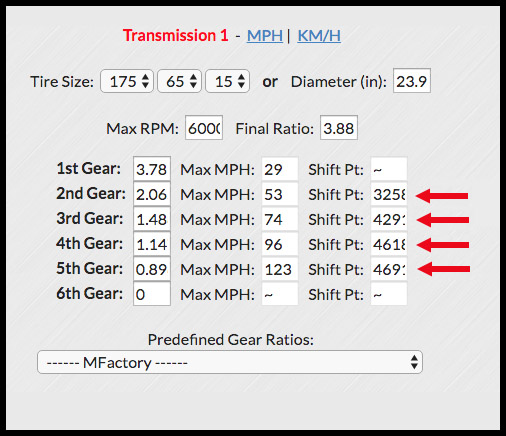

@stangalat you're buying special "beehive" valve springs and all kinds of rigormorole and what-have-you building a bigish engine with Panchitos yadda yadda. Why are you showing shift points below 6000?

Good question @edsnova. Habit, mostly.

I'm interested in where the shift-points are in normal travel. I could've (and probably should have) put in 4000 as the shift-point because that's where I like to shift when I'm being a good boy. I used to plug in redline, but @ALB broke me of the habit in one of the 50 or so PMs we've sent back and forth over the years regarding the perfect 5-speed.

FWIW: Al Blanchette is the residing "king of gears" (all hail the king), at least as I see it. We joke about the holes and the quizzes of new members, but he's been enormously helpful as a resource-- both for knowing where to get stuff and for knowing what is available for gear-stacks. I wish I'd have known him 15 years ago. @Anthony has been equally patient as I've cycled through about 6 different gear combinations. He's an amazing asset to this hobby, and I wish I lived close enough to avail myself of his services without incurring many hundreds of dollars in UPS charges.

Anyhow, this motor should pull to 7000+ RPM, but Panchitos aren't big heads by any metric. They're inexpensive, with 40 mm intakes and 62 mm of port volume. The magic is in the flow and the port velocity-- the "as cast" numbers are crazy: 167 cfm at .500 lift and 300 fps. The net/net is that these heads will work on a hot street motor of pretty much any common displacement.

I've spent way, way, way more money on heads in the past, and they were way, way, way bigger to get those flow numbers (and couldn't hope to get those port velocity numbers). It's the port velocity that should make them drivable, and pleasant as a GT (snappy pull from everywhere in the RPM register) as long as the cam is not too much, and I'm trusting Mr. Downs on that. The CB cam series is super-interesting, with all of them ground on 107* centers rather than the usual 108*. I've never run one before, mostly because the catalog (for cams) is such a mess that it's really hard to find what you are looking for (even the numbers don't correspond to anything). But I'm excited to try this one.

The beehives yada, yada, yada are all me-- my personal desire to complicate something built to be inherently simple. I just love the idea, and being in love with theoretical ideas is what gets me up in the morning.

I'm only happy when it rains.