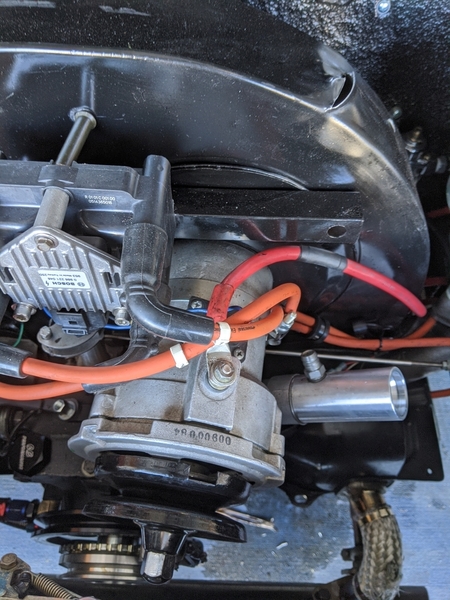

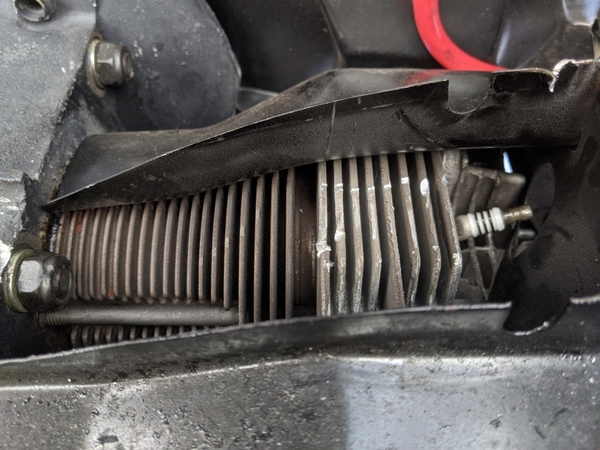

The car's running pretty good, so I've begun my quest to fiddle with it enough to make it run worse. I've been data logging my air fuel ratios at various speeds and engine loads and decided it was pig rich. It is set up with dual Kadron 40s with 130 main jets and 55 idle jets. As I'm sure you all know, but it was news to me (most of my tuning has been fuel injection), the Kadrons run on the idle jets up to 2500-3000 rpm and then on the main jets up to around 4500 rpm and then pretty much depend on the air jets above that. I was seeing low 11s with the 130 mains at full throttle and 11-12s on the idle jets at lower rpm. So, time to play around with smaller jets.

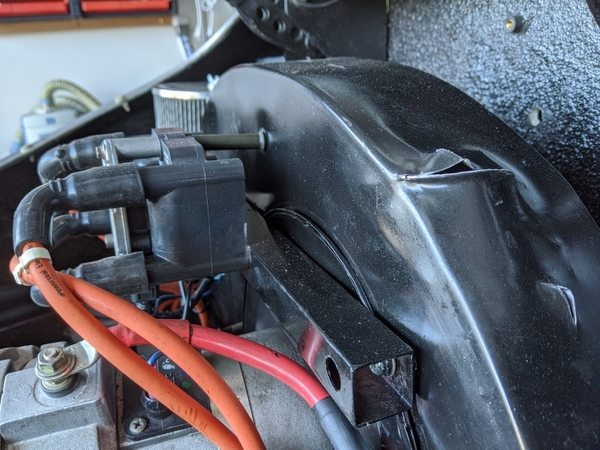

Cheapskate that I am, I checked around for an assortment of jets that didn't break the bank. Thesamba said that Mikuni motorcycle jets were the same as the Kadron/Solex/Brosil jets, and you can find a good assortment of identical jets in smaller sizes than the 130 on Amazon for less than $10. You can also get a kit for PWK Keihin OKO CVK PWM carbs that include "air jets" for the same price. I decided to give the latter a try.

The kit included 10 main jets from size 100 to 140. The PWK Keihin OKO CVK PWM jets have the same threaded part as the Kadron/Mikuni jets but the heads are a bit smaller. I tried the 125 jets and the 120 jets and both worked well. Switching from a 130 to a 125 raised the full throttle AFR by .9. I'm running the 120s right now and seeing full throttle AFR of around 13 at 4000 rpm.

The idle jets in the kit are useless for the Kadron - they are very much the wrong size to replace the originals. It's not worth buying the PWK Keihin OKO CVK PWM kits to get them. Doing it again, I'd just buy the Mikuni assortment.

I looked around for a replacement for the idle jets and there are some on eBay for about the same price that John at aircooled sells his but with free shipping. I figured John has contributed so much of his grumpy expertise to the aircooled community over the years that I'd order the idle jets from him even though it almost doubled the price for shipping (Hawaii problems). I ordered 50s for the idle circuit, we'll see how it goes.

Mike