Ok, thanks for the feedback. I'll cancel the order for the purple crushed velvet, although it was really dreamy. Since I altered the compression specs from my earlier plans, based on your feedback, here's the latest configuration.

- 1776 cc engine: 90.5mm, stroke 69mm, piston deck clearance .040" - compression ratio 8.9

- Dual relief case AJ-144762 - Hoover oiling mods

- Full flow oil pump (30 mm ) w/ external oil filter

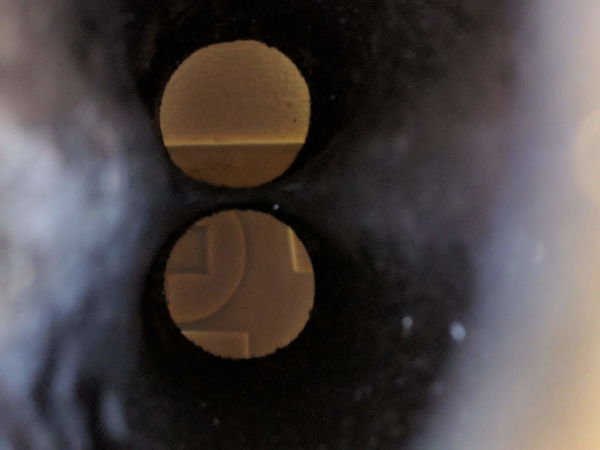

- Panchito 044 double valve spring heads, chamber 50cc

- 1.1:1 stock rockers Hoover modified oil passages w/CBP swivel feet

- Cromoly pushrods

- Hardened lifters

- Berg heavy duty grooved rocker shaft

- Engle W110 camshaft .392" cam lift, .430" valve lift (1.1 Rockers), 284* duration & 247* duration at .050", on 108 lobe center

- 69 mm counter weighted crankshaft

- SCAT 3/8 5.40" balanced connecting rods with ARP 8740 bolts

- Balanced Mahle 90.5 pistons and wrist pins

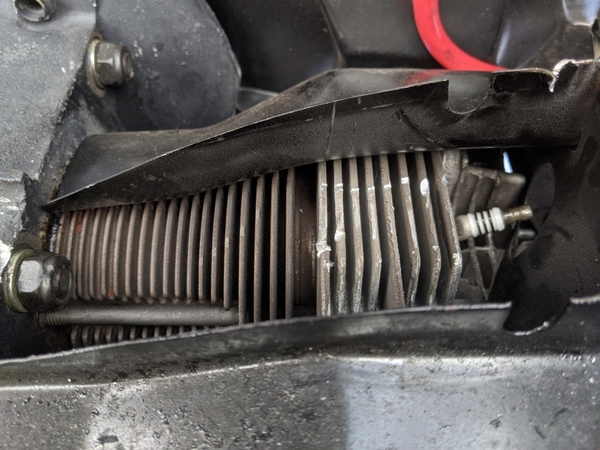

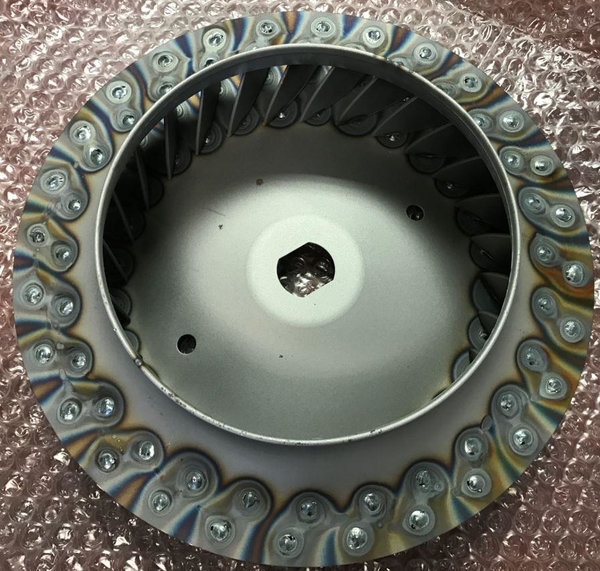

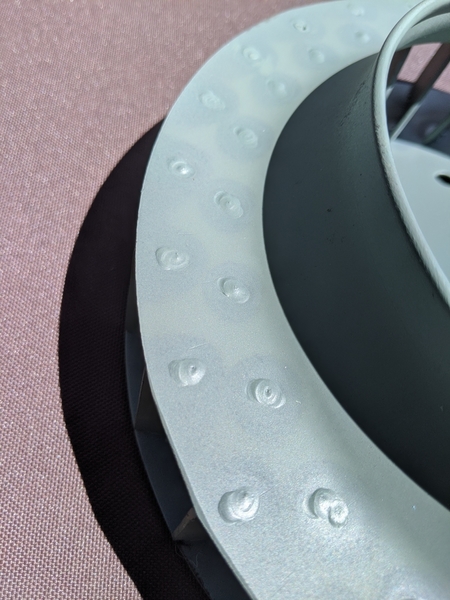

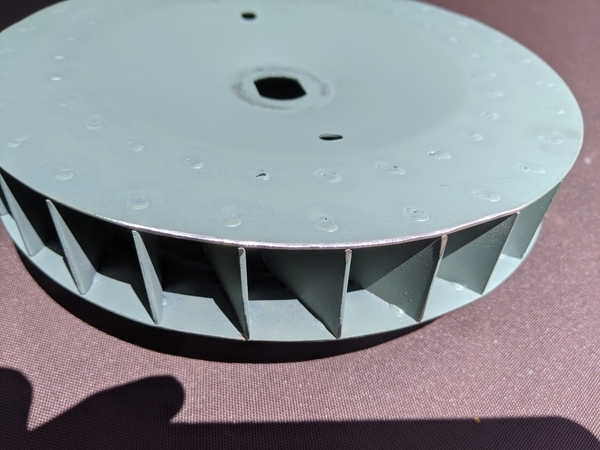

- Berg welded cooling fan

- Dual 40mm Kadrons: 28 venturi, 130 mains, 50 idle (at sea level)

- Ported EMPI intake manifolds (opened up to 1" from bottom)

- Carter P60430 rotary fuel pump

- Holley 12-804 fuel pressure regulator modified for 1.75 psi

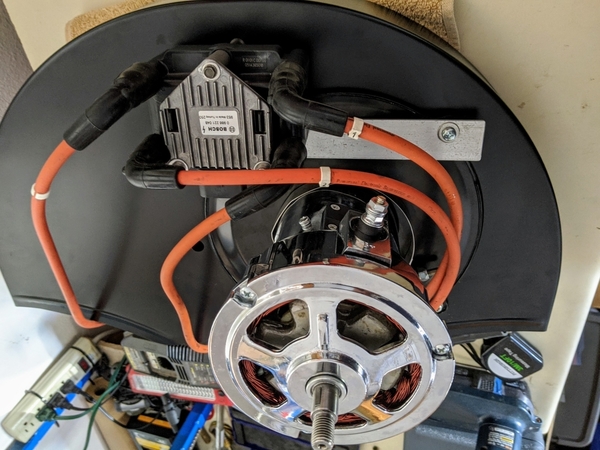

- Bosch high output wasted spark ignition module 032905106F

- CB Performance 36-1 missing tooth wheel and Hall effect crank position sensor

- Speeduino ECU spark controller

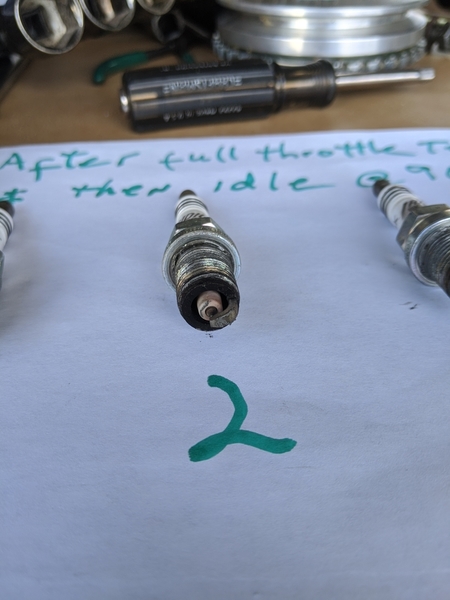

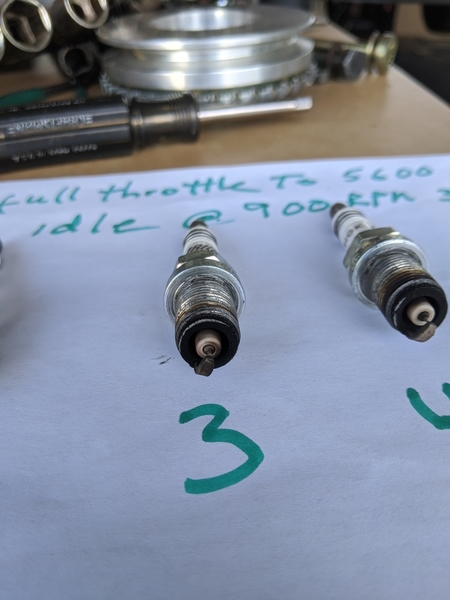

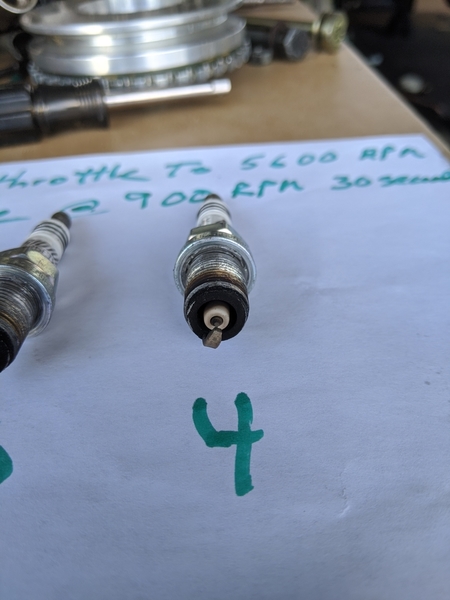

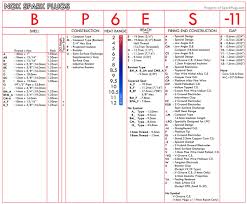

- NGK BKR5EIX-11 IX iridium spark plugs .044" gap

- EMPI US made Chrome 90 amp alternator

- EMPI 4099 13 lb chromoly flywheel

- EMPI 1700 lb model 4080 stage 1 200 mm pressure plate

- 5-3/4" Power pulley

- Vintage Speed Taiwan 1.5" stainless sport exhaust system - 155-204-05200

- Rancho Pro Street IRS Transmission# DC0257471 - 4.125 final gear ratio

- Cromoly spring mounted Hawaiian hula girl dashboard doll

Mike