OK, folks, I've not got started yet but am noticing some things on the kit I need to ask about.

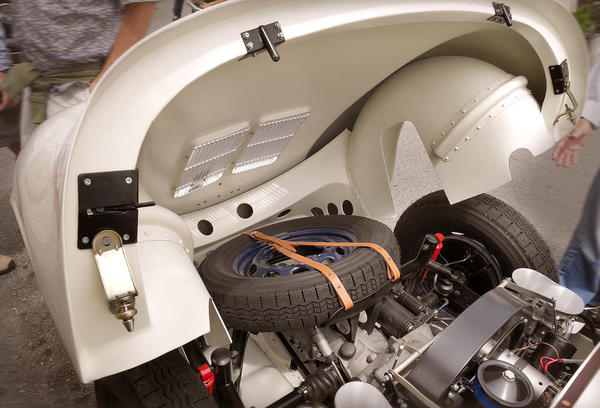

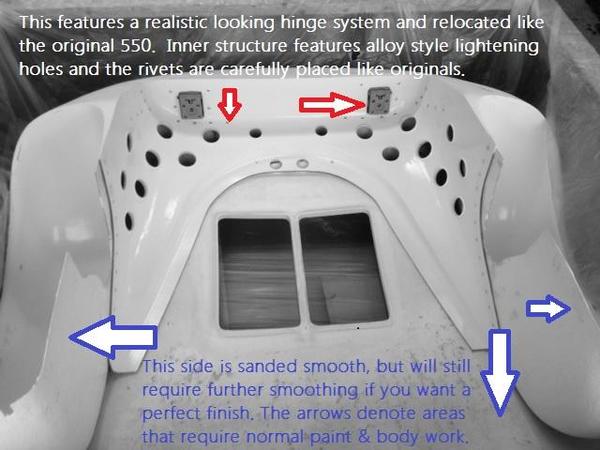

Does the TR Spyder kit come with the fuel fill hole already cut in the hood?

Because mine does not in any way line up with the one in the purported fuel tank.

The tank is sitting in the spot it appears to have to go. It is oriented as it must be. The hole for the filler is where it has to be—the old sender hole, right?

So I figure I'll have to FG over this hole in the hood and cut a new one five inches lower, which is no big deal. But before I start I want to check with everyone to make sure I'm not missing something obvious & there isn't some other, better way.